maxcruiser

Well-Known Member

I seen a thread in here about this mod but no explination on how to do it. I found this step by step proceedure on how to do it on a thread from vmaxchat forum. thought some of you maybe interested. The following is the thread as posted;

This modification is to ease lever pull, increase smoothness and stop wear in lever and pivot bolt

Parts required

1- clutch lever

1- Pivot bolt (clutch)

1- Bearing INA # HK 0810

1- 12mm drill bit

Locktite # 609 or # 680, stud and bearing retaining compound

Step 1

Drill hole in clutch lever with 12mm drill bit, be sure it?s straight.

Step 2

Slightly chamfer drilled hole to assist in installing bearing.

Step 3

Put a small drop of Locktite on out surface of bearing.

Step 4

Press carefully bearing into lever, press in till flush with lever.

Step 5

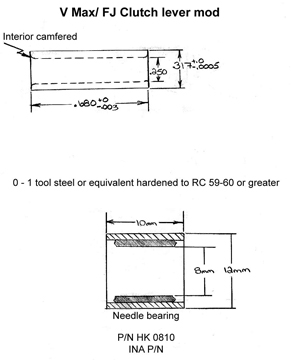

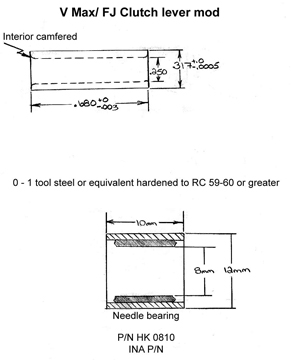

Have hardened sleeve made as per diagram. Use inside diameter of bearing as a guide to fit of sleeve, it should just slide in without force.

Step 5

Have Machinist turn down stock bolt as per diagram, so sleeve slides over modified bolt

Step 6

Use Locktite on inside of sleeve and press onto bolt. Allow time to set.

Step 7

Lube bearing and bolt with waterproof grease and reassemble clutch lever to master cylinder.

Step 8

Go try it out and feel the difference, no up and down lever play and very smooth and controllable lever pull.

This modification is to ease lever pull, increase smoothness and stop wear in lever and pivot bolt

Parts required

1- clutch lever

1- Pivot bolt (clutch)

1- Bearing INA # HK 0810

1- 12mm drill bit

Locktite # 609 or # 680, stud and bearing retaining compound

Step 1

Drill hole in clutch lever with 12mm drill bit, be sure it?s straight.

Step 2

Slightly chamfer drilled hole to assist in installing bearing.

Step 3

Put a small drop of Locktite on out surface of bearing.

Step 4

Press carefully bearing into lever, press in till flush with lever.

Step 5

Have hardened sleeve made as per diagram. Use inside diameter of bearing as a guide to fit of sleeve, it should just slide in without force.

Step 5

Have Machinist turn down stock bolt as per diagram, so sleeve slides over modified bolt

Step 6

Use Locktite on inside of sleeve and press onto bolt. Allow time to set.

Step 7

Lube bearing and bolt with waterproof grease and reassemble clutch lever to master cylinder.

Step 8

Go try it out and feel the difference, no up and down lever play and very smooth and controllable lever pull.

![Bovemanx Motorcycle Phone Mount Holder, [150mph Wind Anti-Shake][7.2inch Big Phone Friendly] Bike Phone Holder, Motorcycle Handlebar Cell Phone Clamp, Compatible with iPhone 16 Pro Max Smartphones](https://m.media-amazon.com/images/I/51F+1sontPL._SL500_.jpg)