naughtyG

Well-Known Member

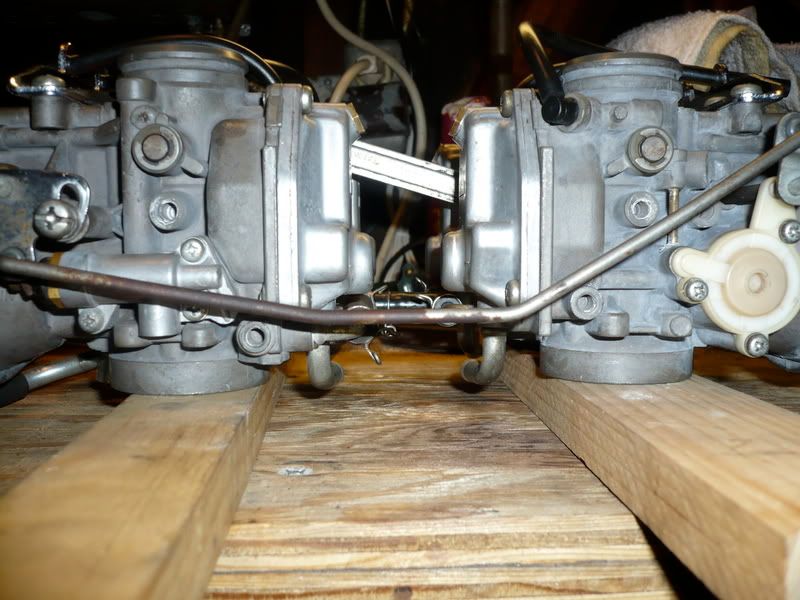

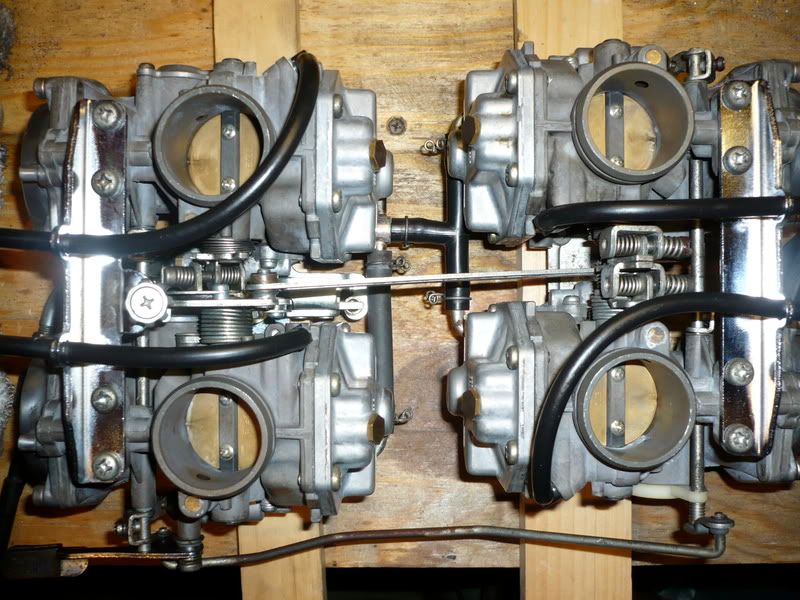

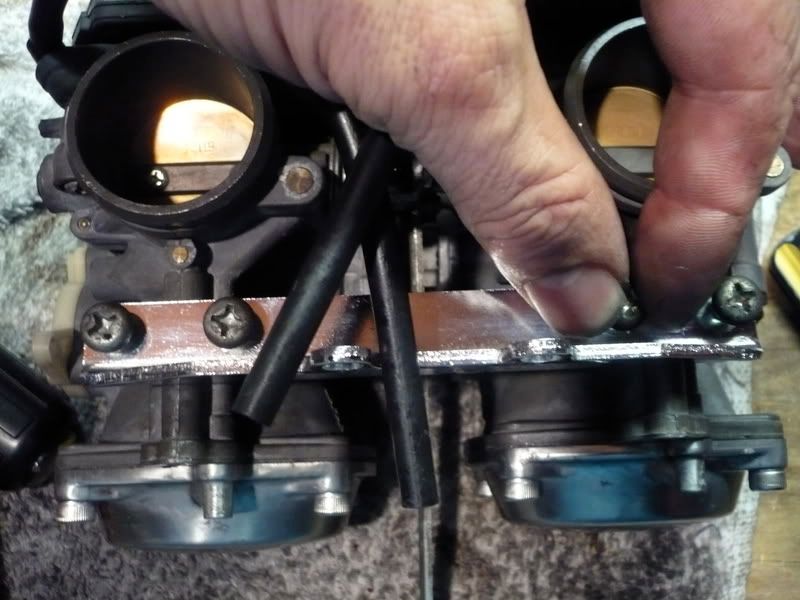

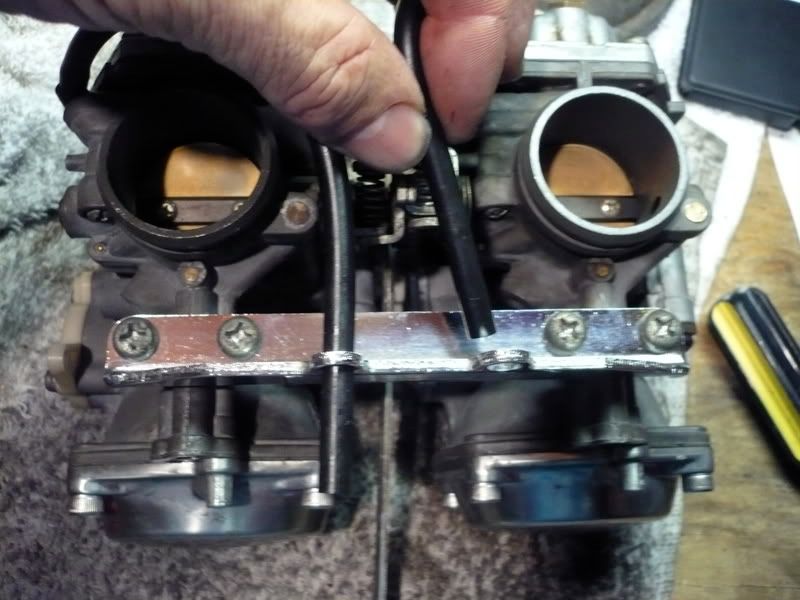

As I just cleaned / rebuilt my carbs, I thought I'd document the process, especially the re-assembly since we already have plenty of instructions here as how to take 'em out and apart.

Because I took a lot of pics and didn't want this thread to take 4eva loading every time you open it, I divided it into multiple parts.

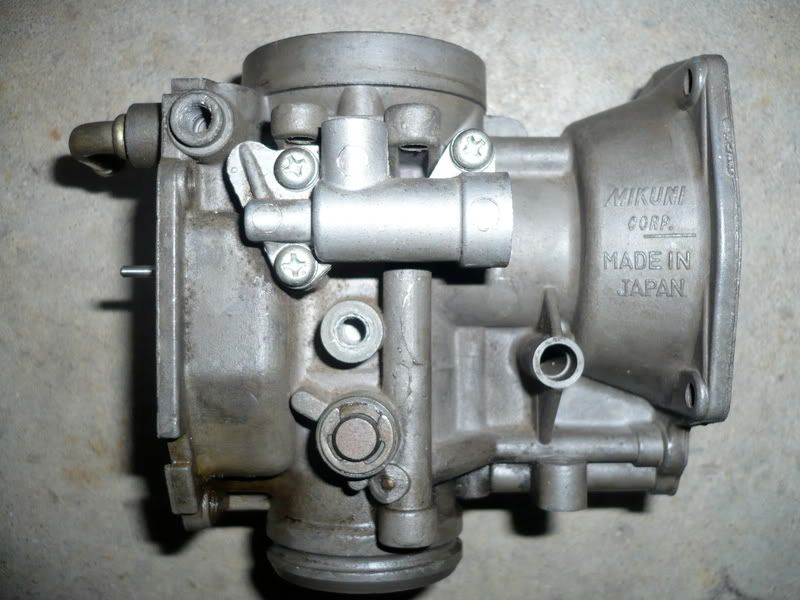

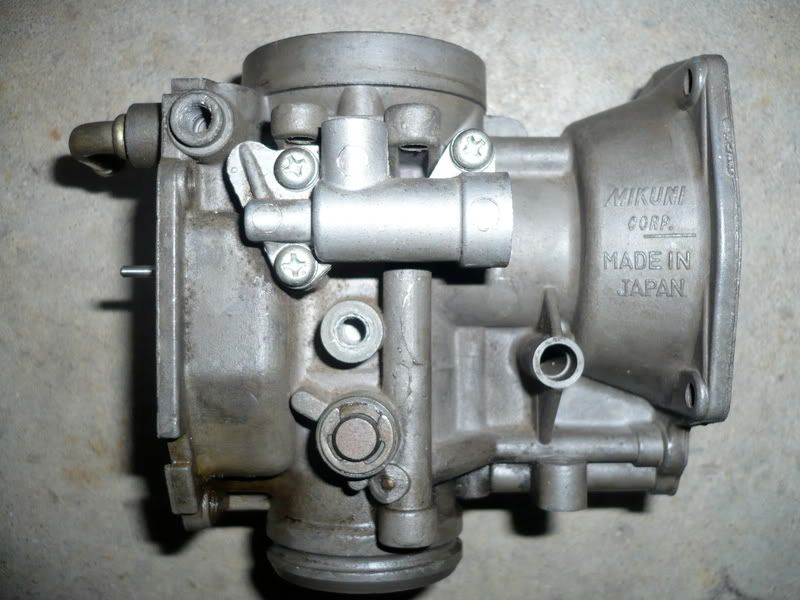

Here's Part 1 - starting with my dirty 'ol carb:

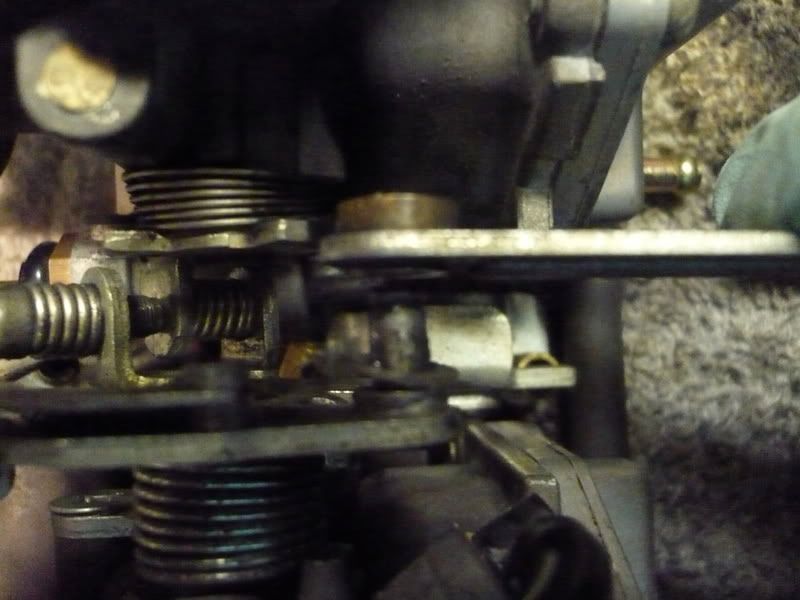

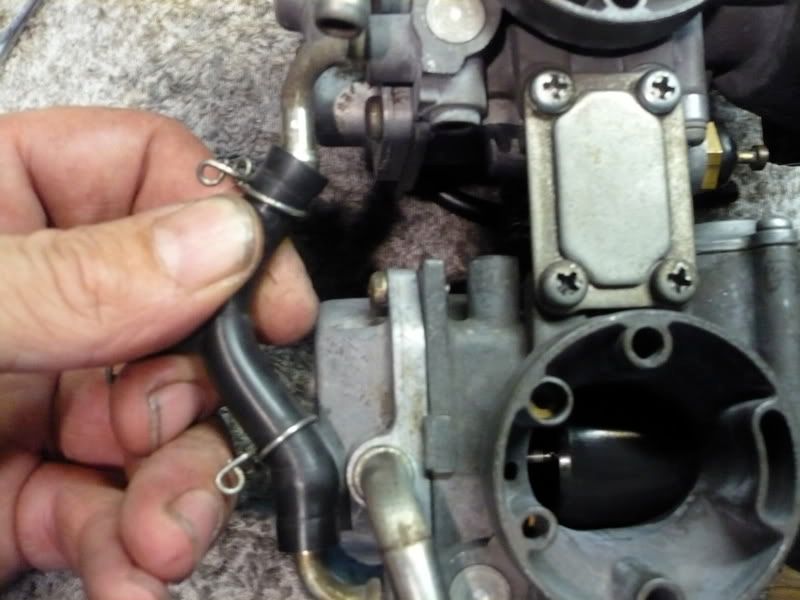

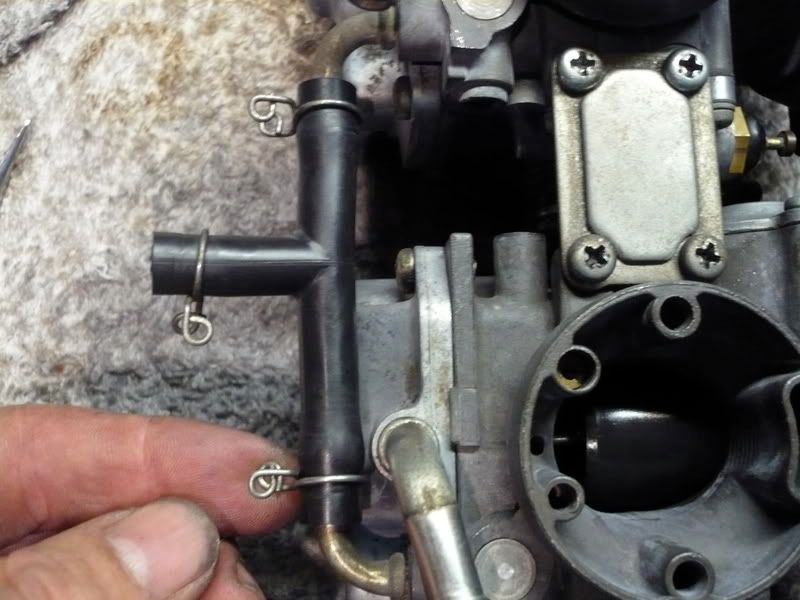

Starter plunger has been removed, but as advised by Mark, I didn't remove the housing as it wasn't leaking

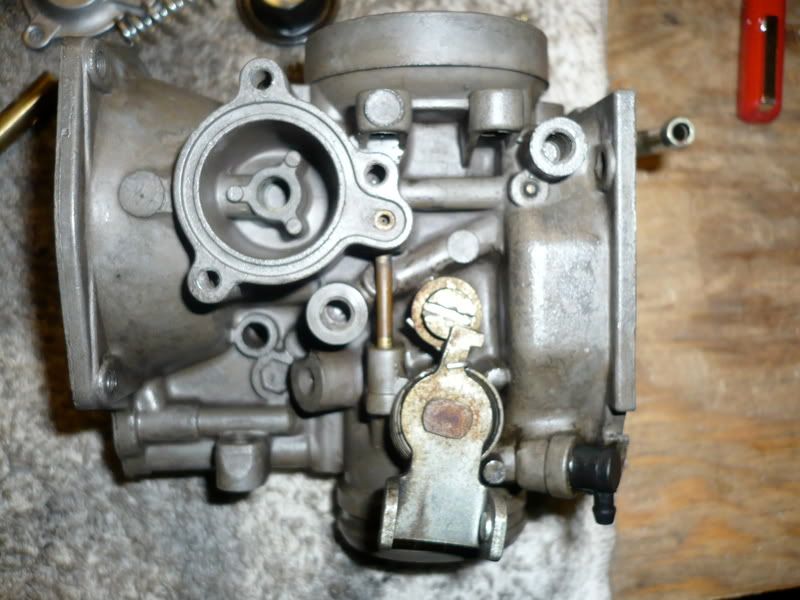

looking at the slide opening - you can see my (very damaged by POs) PAJ2

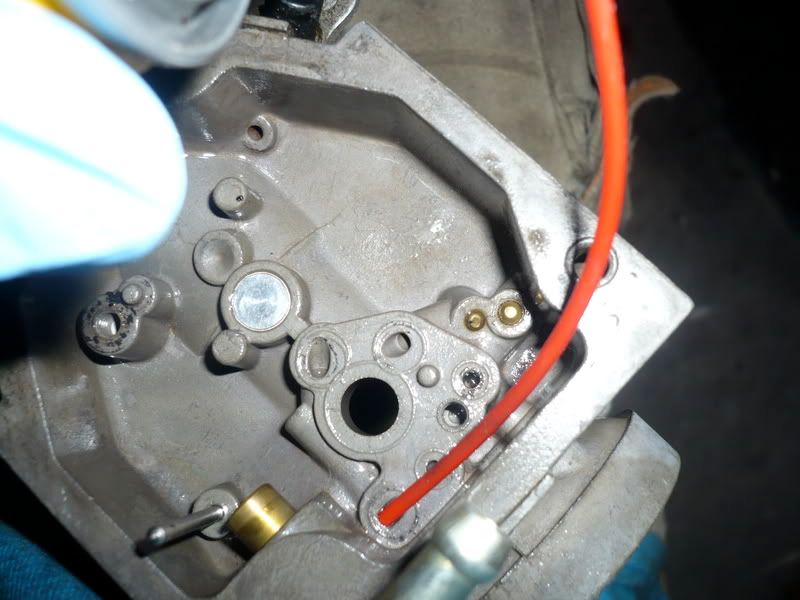

Other side view showing removed coasting enrichener and all the dirt from a leaking fuel bowl

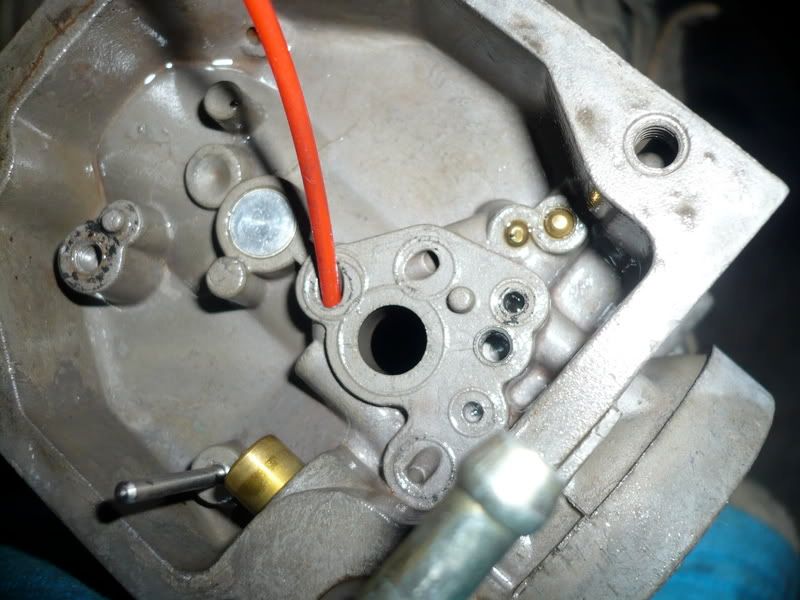

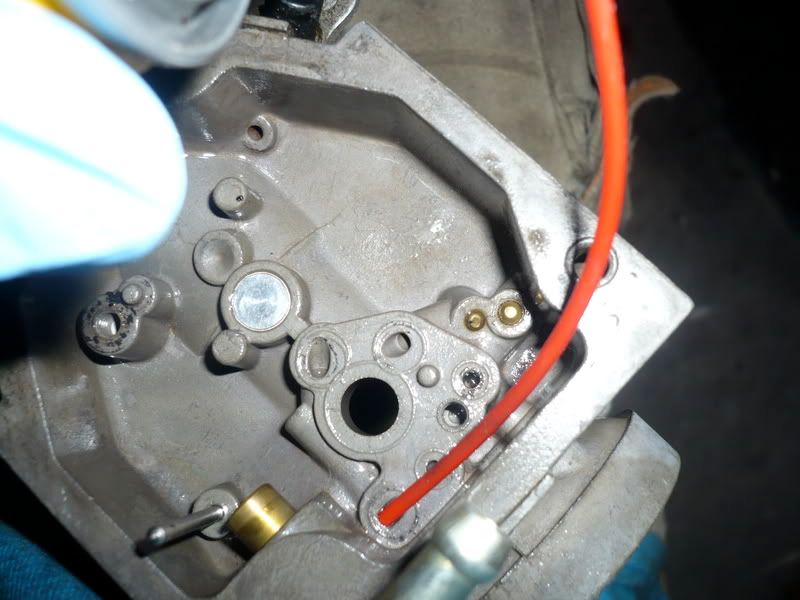

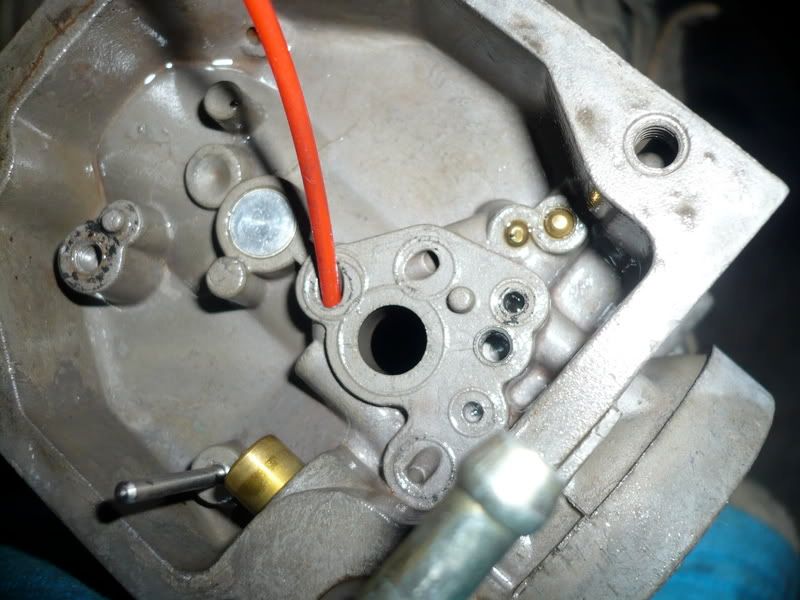

Looking into the empty fuel bowl - float, needle valve, jet block and needle jet all removed

Time to give the outside a good clean, I used Purple Power and a clean new paintbrush

then blew it all dry with compressed air

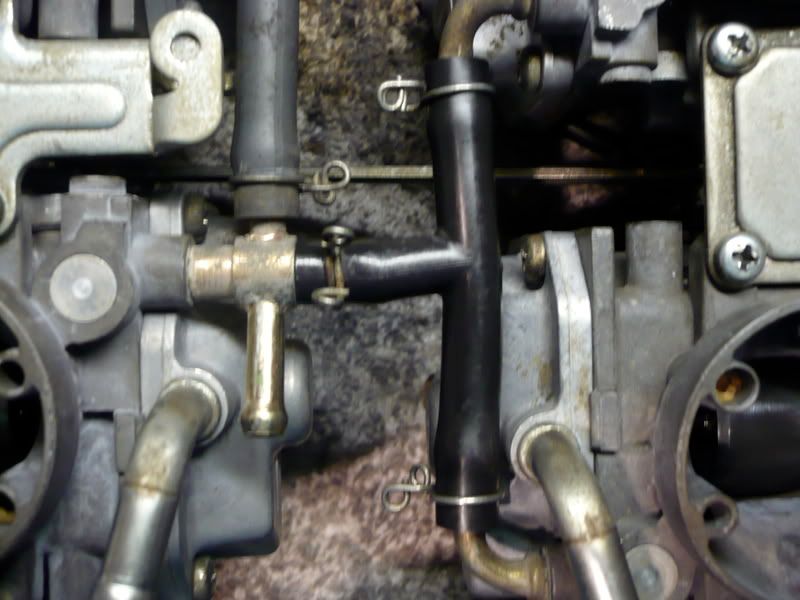

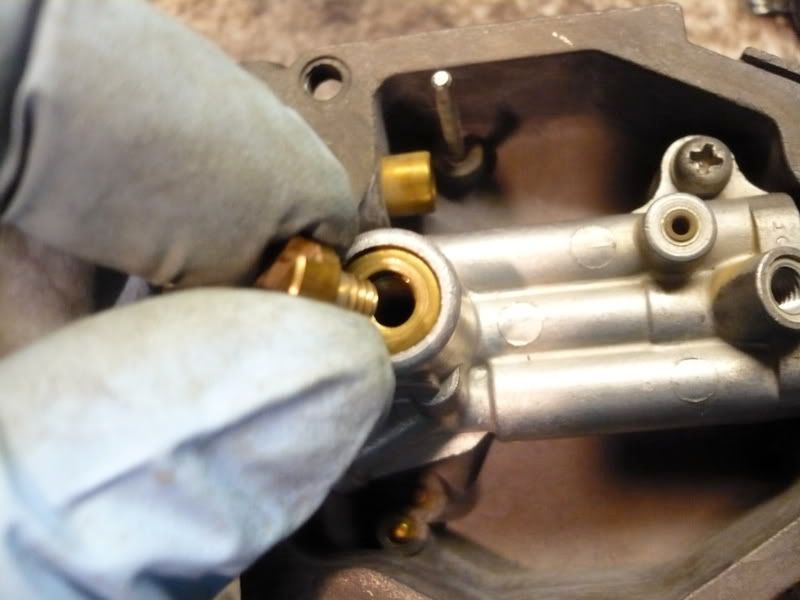

Then I penetrated every single orifice with the Carb Cleaner straw - PAJ1 hole first

air bleed hole

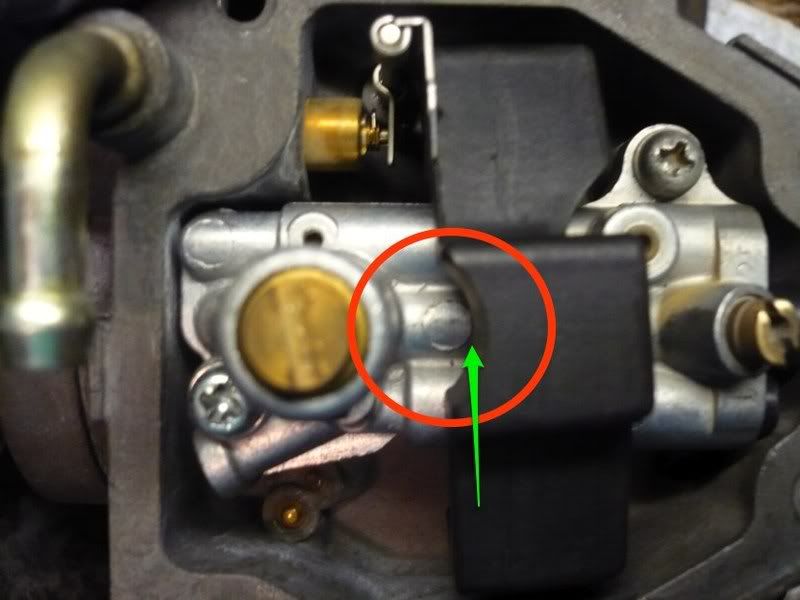

PAJ2 (only thing I could not remove)

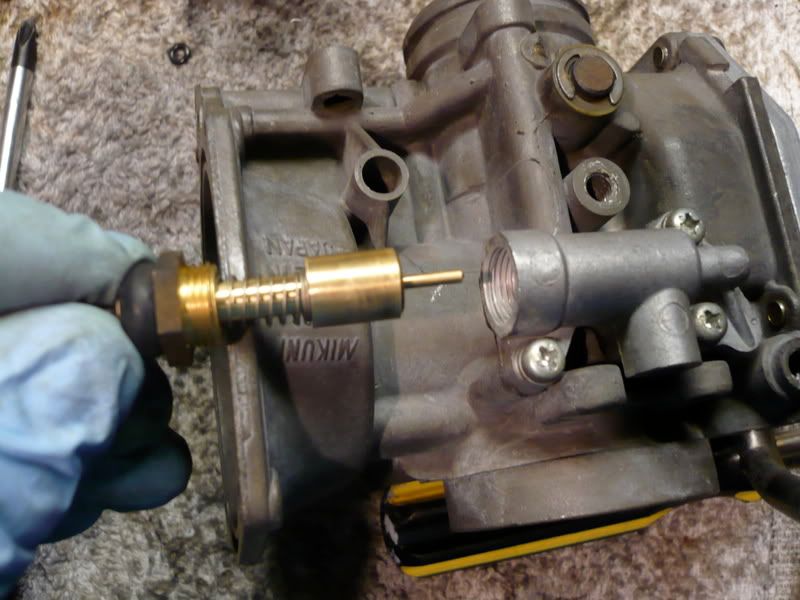

Air/Fuel screw hole

the hole next to it

starter plunger orifice

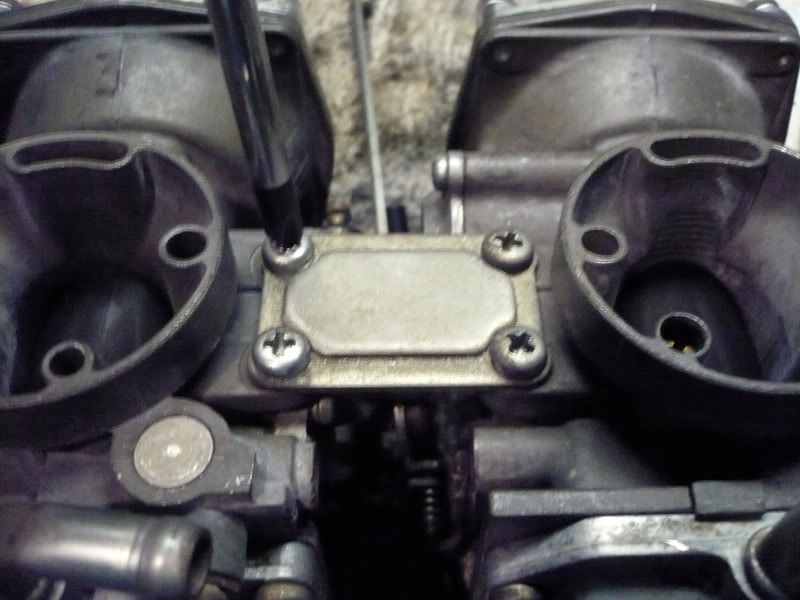

Every hole under the jet block - you can see how some are dirty

needle valve seat

fuel bowl bleed exit

holes behind the throttle in the venturi

coastng enrichener

vacuum to the CE

And then blew every one of these holes with compressed air and repeated the process. No more dirt in my carb - and did that for all four of them. :eusa_dance:

Because I took a lot of pics and didn't want this thread to take 4eva loading every time you open it, I divided it into multiple parts.

Here's Part 1 - starting with my dirty 'ol carb:

Starter plunger has been removed, but as advised by Mark, I didn't remove the housing as it wasn't leaking

looking at the slide opening - you can see my (very damaged by POs) PAJ2

Other side view showing removed coasting enrichener and all the dirt from a leaking fuel bowl

Looking into the empty fuel bowl - float, needle valve, jet block and needle jet all removed

Time to give the outside a good clean, I used Purple Power and a clean new paintbrush

then blew it all dry with compressed air

Then I penetrated every single orifice with the Carb Cleaner straw - PAJ1 hole first

air bleed hole

PAJ2 (only thing I could not remove)

Air/Fuel screw hole

the hole next to it

starter plunger orifice

Every hole under the jet block - you can see how some are dirty

needle valve seat

fuel bowl bleed exit

holes behind the throttle in the venturi

coastng enrichener

vacuum to the CE

And then blew every one of these holes with compressed air and repeated the process. No more dirt in my carb - and did that for all four of them. :eusa_dance:

![Bovemanx Motorcycle Phone Mount Holder, [150mph Wind Anti-Shake][7.2inch Big Phone Friendly] Bike Phone Holder, Motorcycle Handlebar Cell Phone Clamp, Compatible with iPhone 16 Pro Max Smartphones](https://m.media-amazon.com/images/I/51F+1sontPL._SL500_.jpg)