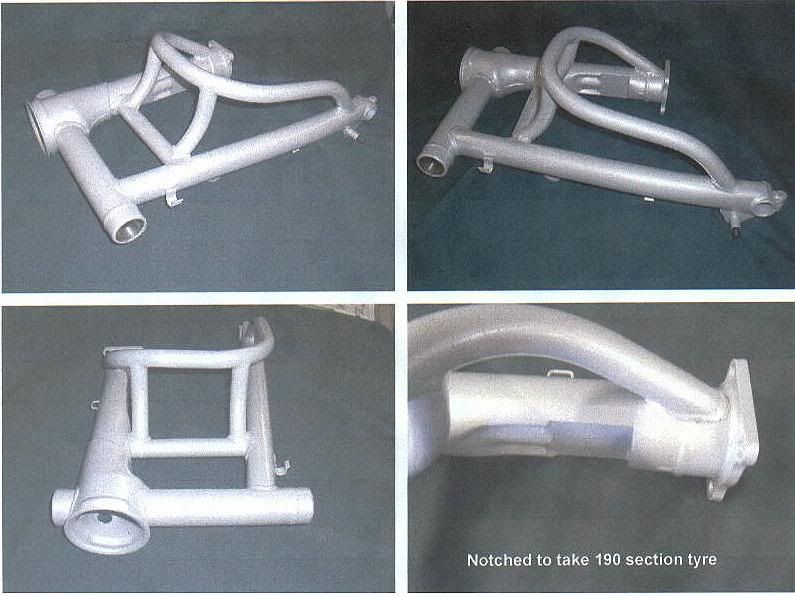

As stated, it was notched so much that I had about 1/16 of inch clearance between the tire and drive shaft shaft to get the 1/16 of clearance. I knew with tire speed it would narrow and grow taller, so I didnt worry about sidewall rubbing the shaft at high speed. I also had to place a washer between wheel and the differential spline to move the rim over to the right. This was a wide tire! Cross Section was almost 9 inches.

But that slick hooked no matter what with a short burnout in the box at the track. I even rode it on the street a few times with that big ass slick on,, talk about an unstable ride between the tall soft sidewalls and swingarm flex it was a handful to ride on the street!

It was crazy! It served its purpose as an expierence, and I knew if it failed I would have to pay for idea and the obvious risk that it involved.

I will update with the new swingarm on the bike and its handling difference. Hopefully I will have it Thursday afternoon. I am just going to powder coat Thursday and put it on Friday morning.

We been having some great weather here in Central TN mid 80's with real low humidity in the low 80's normally 100+ with a heat index of 110+

Lankey,

you dish out more **** than anyone on this forum, in the name of humour of course....Right???? at least that is what you say when called on it.....You need to learn to take it as well......You attack me a like a 3 year old instead.......

No one in all the years I've been messing with maxes, reading on every forum and newsgrup there is has ever broken a swingarm driveshaft tube except you, you're talented that's for sure........

So is it really a great big leap to think that cutting a hunk of metal out of the support system that keeps the pumpkin from counter-rotating in the opposite direction of the rear wheel, whithout devising any method to add strength back to it afterword, was the cause of you failure???

Of course not, it was no doubt the clear and direct cause of your failure...I merely pointed it out for you........

I'm not the one that screwed your driveshaft up, blame that guy, not me.......

You just admitted above it was a failed experiment...so why attack me for pointing out that cutting a notch without filling the hole back in was a ******* idea......??? You probably knew it was a bad idea when you did it anyway, after all, with your racing experience you can't be that stupid I hope........

I also thinks it's disengenous to make multiple posts attacking how ****** the max handles, using yours as a baseline, when you weakend the driveshaft to the point of immenent failure...and continue making those posts.......Like I said, no wonder your bike handled poorly and no wondered it was a frame flexing wobbler.

As for your comment about filling a hole back in after digging, I also think that you knew exactly what I meant and it's disengenous (look it up if you need to) to present an argument like that, everyone on this forum except you? knows what is meant by filling the notch back in, rather than leaving it open,

The plate I put over my notch is running about .030 from the driveshaft, and the plate is 12 guage metal, it's not that much room to give up for a stronger swingarm

![Aomiker Motorcycle Phone Holder Mount - [Metal Extension Arm] [Dual Vibration Dampener] Motorcycle Cell Phone Mount, Bike Phone Handlebar Clamp for iPhone 16 15 14 13 Pro Max Plus, 4.7-6.7" Smartphone](https://m.media-amazon.com/images/I/51gU2g5VxgL._SL500_.jpg)

![JOYROOM Motorcycle Phone Mount, [1s Auto Lock][100mph Military Anti-Shake] Bike Phone Holder for Bicycle, [10s Quick Install] Handlebar Phone Mount, Compatible with iPhone, Samsung, All Cell Phone](https://m.media-amazon.com/images/I/5113ZNM8R8L._SL500_.jpg)

![Lamicall Motorcycle Phone Mount Holder - [Dual Vibration Dampener] [720° Adjustment Arm] Motorcycle Cell Phone Holder, Bike Handlebar Phone Mount, for iPhone 16/15/ 14/13 Pro Max, 4.7-6.7" Phones](https://m.media-amazon.com/images/I/41g9IDInCIL._SL500_.jpg)

![Bike Phone Mount Holder, [Camera Friendly] Motorcycle Phone Mount for Electric Scooter, Mountain, Dirt Bike and Motorcycle - 360° Rotate Suitable for iPhone & Android Smartphones from 4.5-7.0 inches](https://m.media-amazon.com/images/I/51ZirRrsA+L._SL500_.jpg)

![Bovemanx Motorcycle Phone Mount Holder, [150mph Wind Anti-Shake][7.2inch Big Phone Friendly] Bike Phone Holder, Motorcycle Handlebar Cell Phone Clamp, Compatible with iPhone 16 Pro Max Smartphones](https://m.media-amazon.com/images/I/51F+1sontPL._SL500_.jpg)