supervetteracer

Active Member

I'm confused. Perhaps you guys can help shed a bit of light on this.

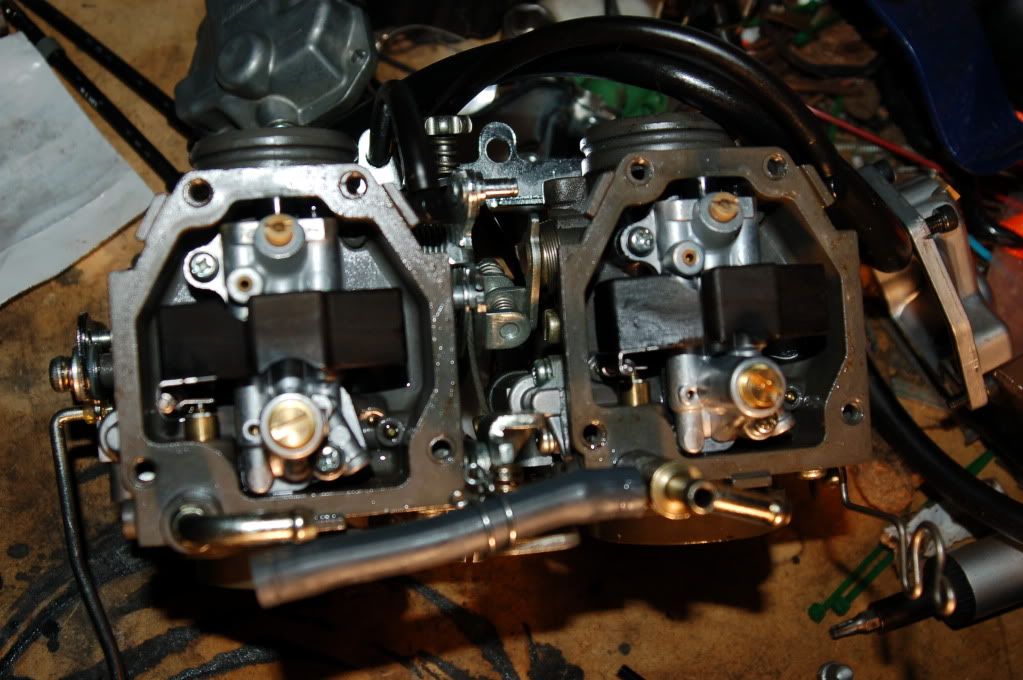

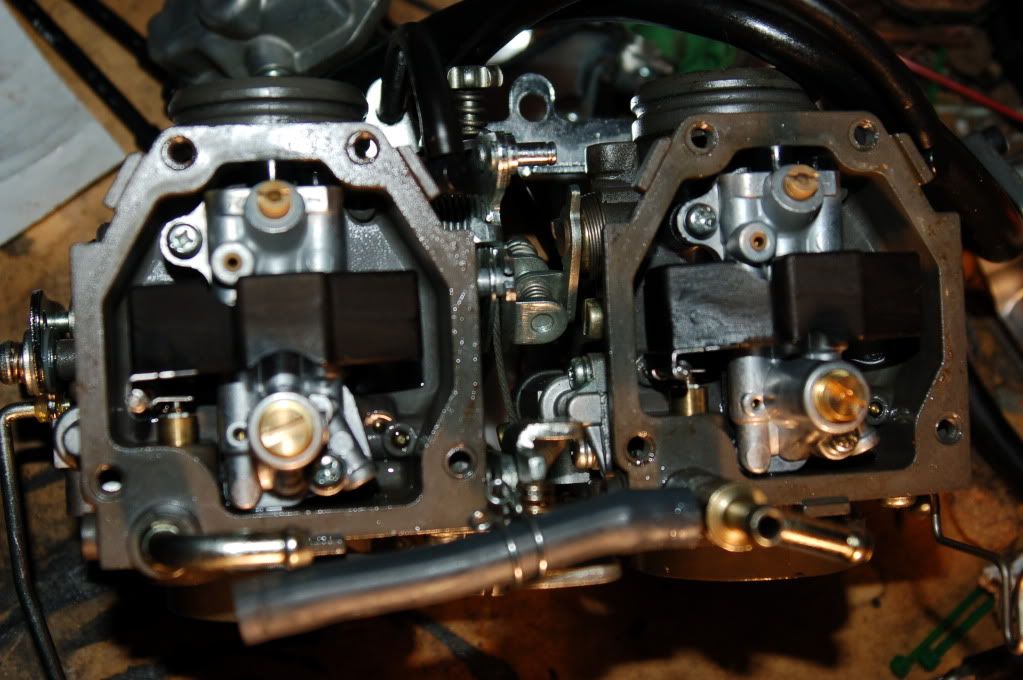

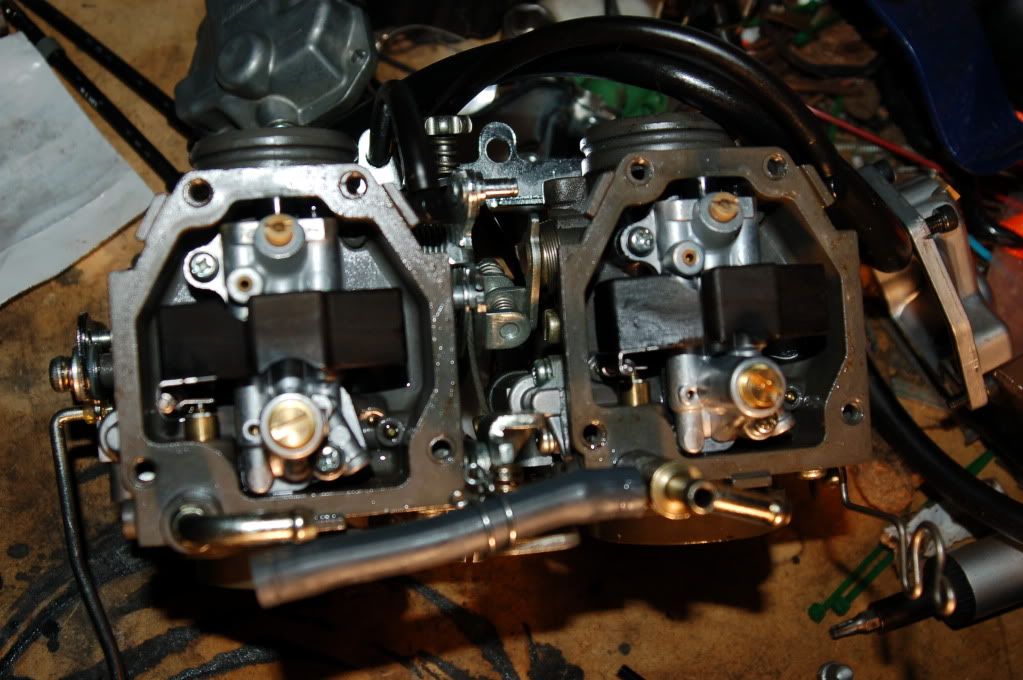

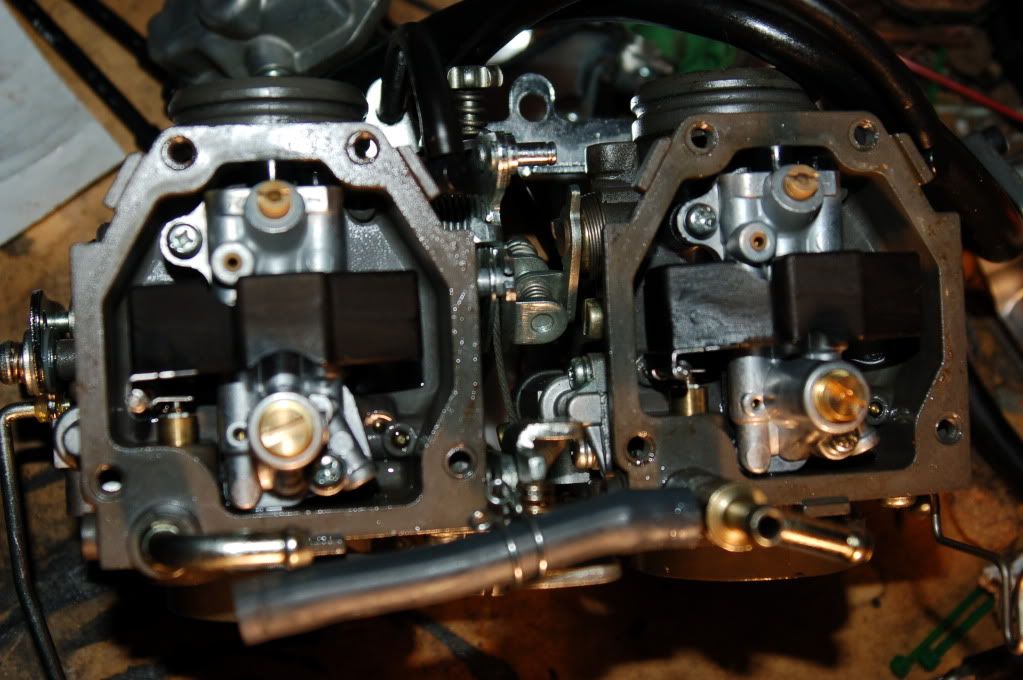

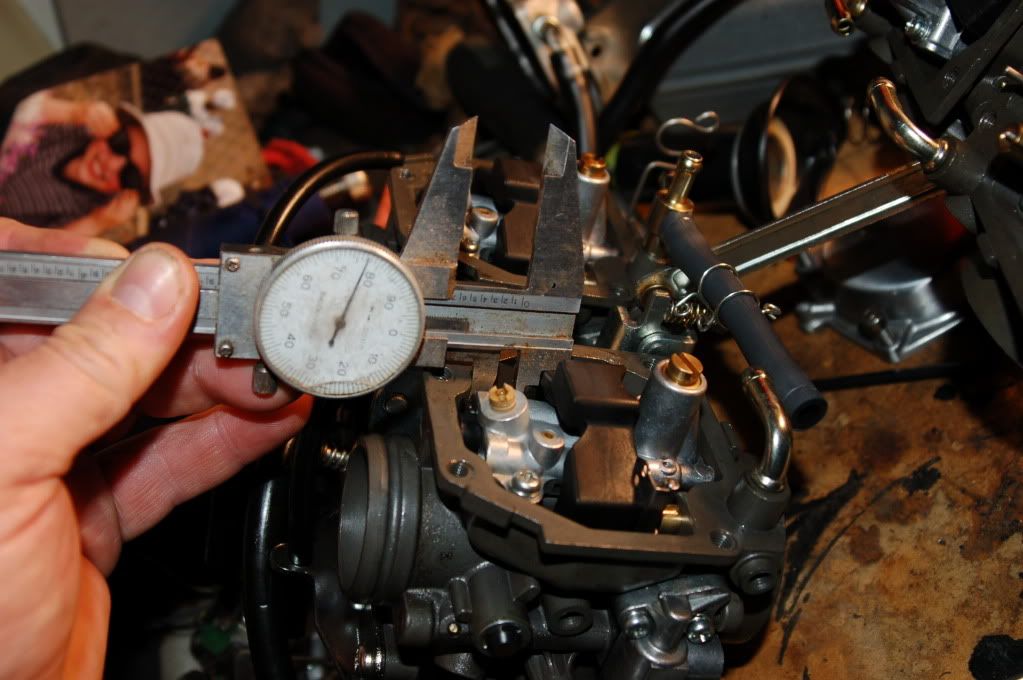

First off this is what I see when I open the floatss on unaltered carbs from an 01.

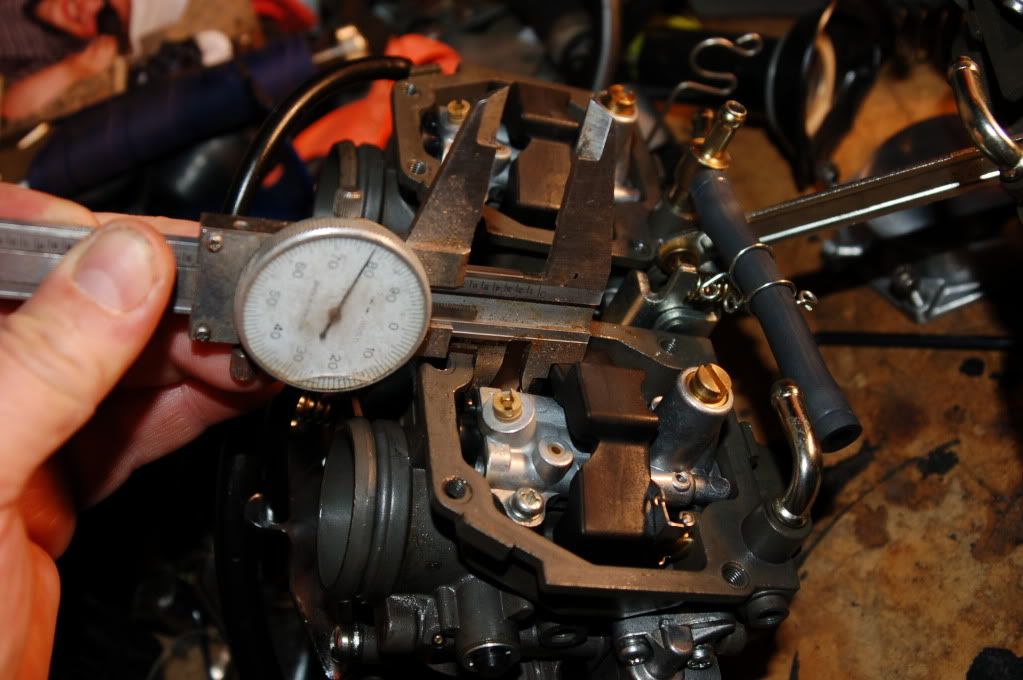

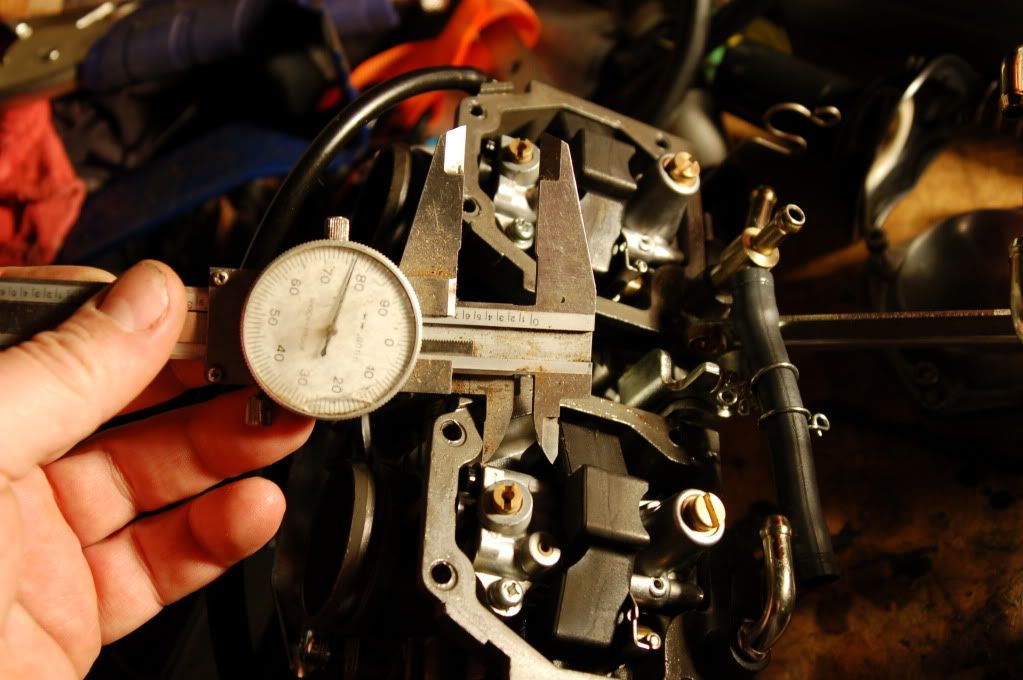

And here is where I am measuring from.

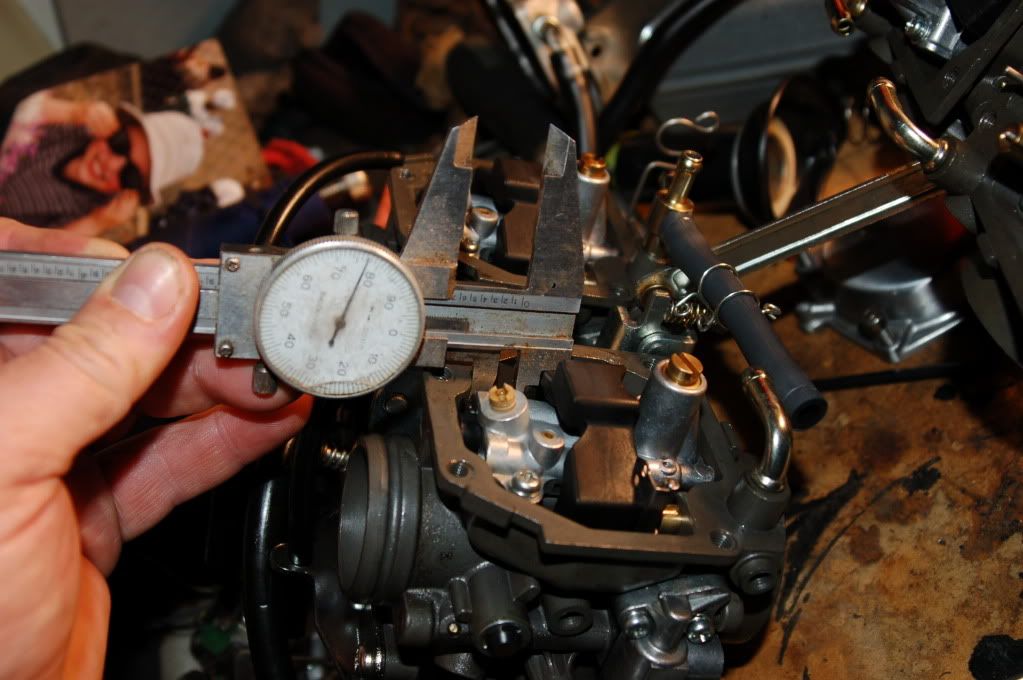

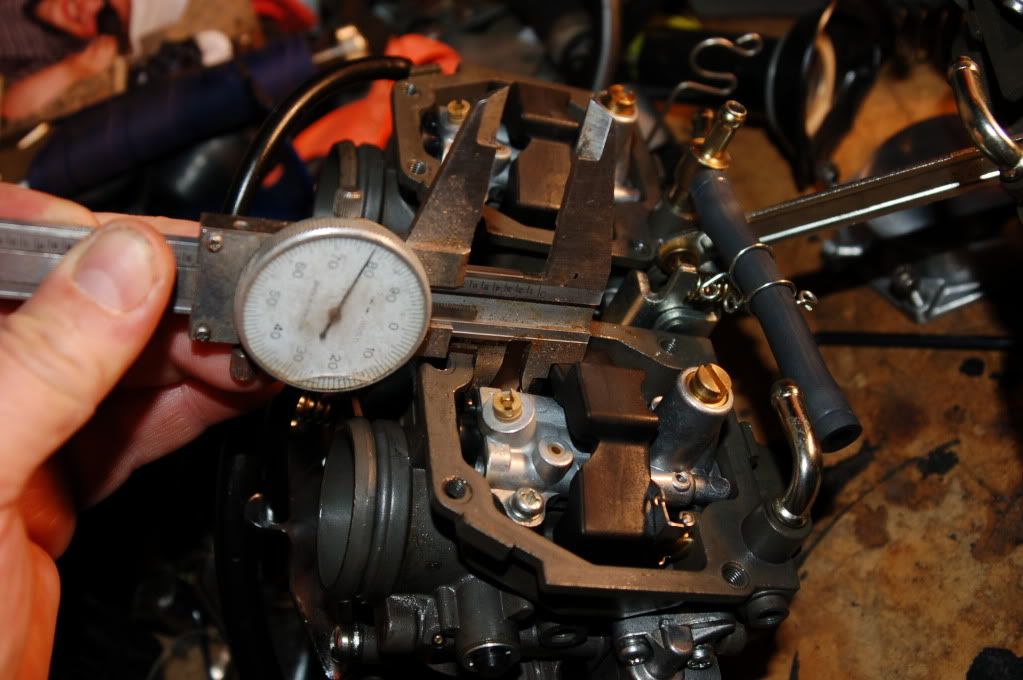

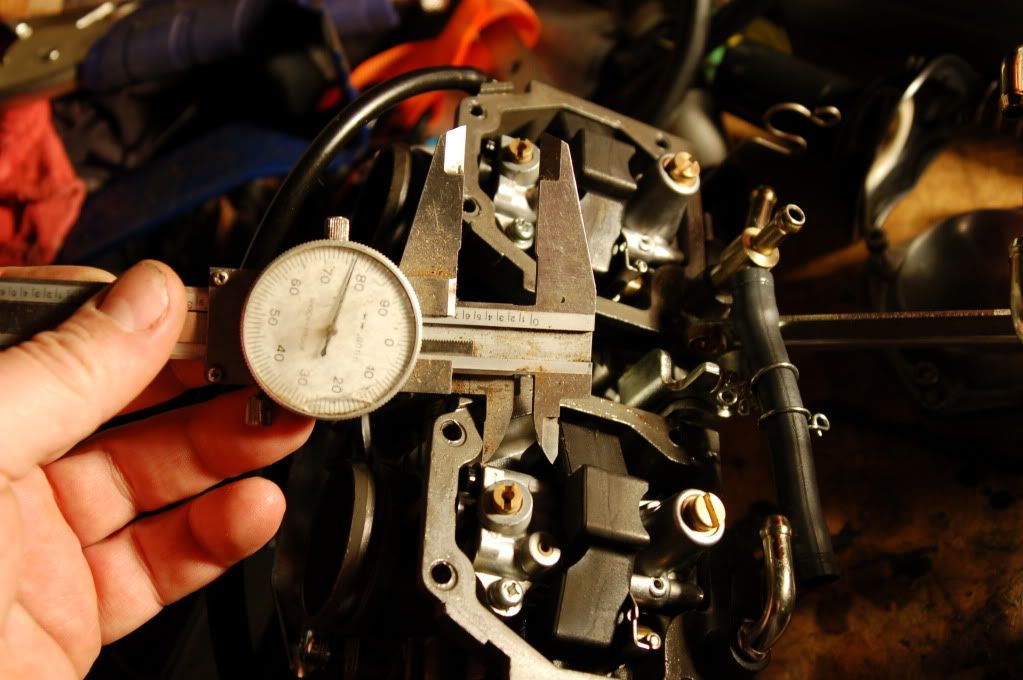

And this is the reading I have.

Am I measuring from teh correct place? Do these floats need to be adjusted?

First off this is what I see when I open the floatss on unaltered carbs from an 01.

And here is where I am measuring from.

And this is the reading I have.

Am I measuring from teh correct place? Do these floats need to be adjusted?

![Bovemanx Motorcycle Phone Mount Holder, [150mph Wind Anti-Shake][7.2inch Big Phone Friendly] Bike Phone Holder, Motorcycle Handlebar Cell Phone Clamp, Compatible with iPhone 16 Pro Max Smartphones](https://m.media-amazon.com/images/I/51F+1sontPL._SL500_.jpg)