F 18 Driver

Active Member

Hi everyone,

SAVE YOURSELF HOURS OF FRUSTRATION A MUST HAVE TOOL FOR JAPANESE MOTORCYCLE REPAIR.

Further, I would recommend a JIS screwdriver with a built-in impact (built-in impact driver)… Which I have listed below with a picture vessel 980

Below are not my words but I'm going to quote articles for this treatise from the Internet and include a few pictures in order to save time.

"It is rather hard to believe, that after all these years of mangling Phillips screws on Japanese bikes, more people (many of them professional mechanics) don’t know about JIS screwdrivers – Japanese Industry Standard.

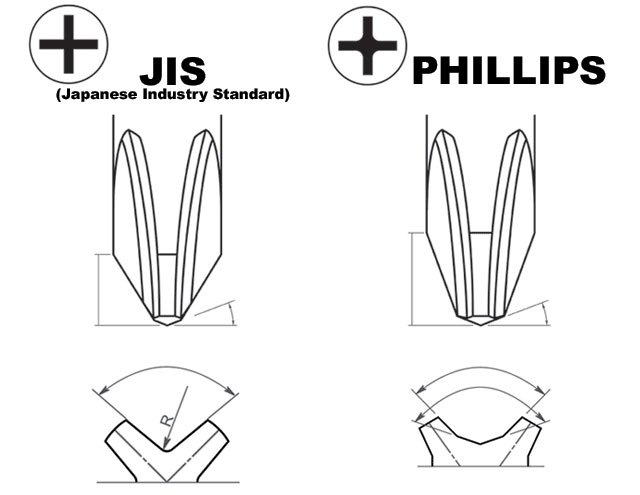

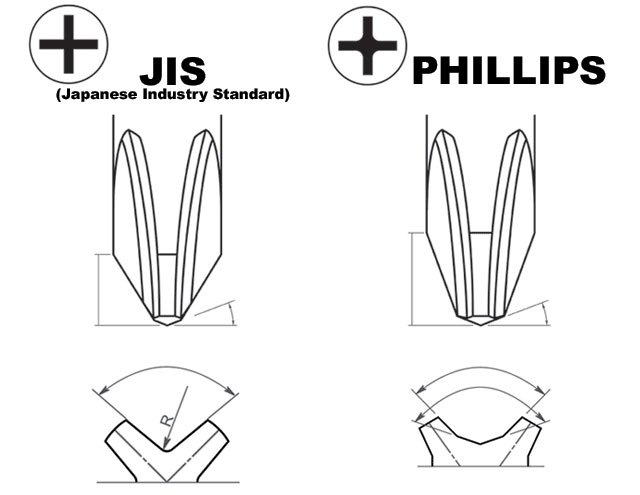

Looking at a JIS tool next to a regular Phillips screwdriver, most people are hard-pressed to tell the differences, but they are definitely there.

Ninety-percent of the time, a regular Phillips will work on a JIS screw; but it’s that other 10% that gets us swearing, then throwing things – those tight screws holding on your carburetor float bowls being particularly devilish once they’re past about two decades of non-removal.

That’s when the right tool can make all the difference. The right tool is a JIS screwdriver, which just fits better in a JIS screwhead and is designed to let you apply more torque than a Phillips driver.

"The Phillips system was invented for use in assembling aluminum aircraft, with the object of preventing assemblers from tightening screws so tightly that the aluminum threads strip.

The driver will “cam out” before that happens. The Phillips driver has four simple slots cut out of it, each slot is the result of two machining processes at right angles.

The result of this process is that the arms of the cross are tapered and has slightly rounded corners in the tool recess.

Phillips is designed so that when excess torque is applied it will cam out rather than ream the recess and destroy the bit.

Japanese Industry Standard: Often improperly referred to as Japanese Phillips. Commonly found in Japanese equipment, JIS looks much like a Phillips screw, but is designed not to cam out and will, therefore, be damaged by a Phillips screwdriver if it is too tight. Heads are usually identifiable by a single raised dot to one side of the cross slot.

Most people and companies outside of Japan have absolutely no idea what they are. With the similarity in appearance to the Phillips the screws are often damaged in removing and installing with the wrong tools.

JIS tends not to cam out like Phillips. The JIS driver can be used on Phillips quite easily but not reciprically (sic). Drivers are easily available in North America, try Amazon and/or eBay.

JIS-spec cross-head screws are generally marked with a single raised dot or an “X”. JIS always fit Phillip fasteners, but because of slight design differences, Phillips drivers may not fit JIS fasteners. (unless the tip is ground down a bit)."

Easily available via Amazon or eBay

This Vessel Megadora 980 Impacta P2x100 #2 Cross Point Impact JIS Screwdriver, which combines an impact driver with a screwdriver, will save you untold grief . An internal cam mechanism turns the tip 12 degrees per hammer blow

Non-impacted JIS screwdrivers

SAVE YOURSELF HOURS OF FRUSTRATION A MUST HAVE TOOL FOR JAPANESE MOTORCYCLE REPAIR.

Further, I would recommend a JIS screwdriver with a built-in impact (built-in impact driver)… Which I have listed below with a picture vessel 980

Below are not my words but I'm going to quote articles for this treatise from the Internet and include a few pictures in order to save time.

"It is rather hard to believe, that after all these years of mangling Phillips screws on Japanese bikes, more people (many of them professional mechanics) don’t know about JIS screwdrivers – Japanese Industry Standard.

Looking at a JIS tool next to a regular Phillips screwdriver, most people are hard-pressed to tell the differences, but they are definitely there.

Ninety-percent of the time, a regular Phillips will work on a JIS screw; but it’s that other 10% that gets us swearing, then throwing things – those tight screws holding on your carburetor float bowls being particularly devilish once they’re past about two decades of non-removal.

That’s when the right tool can make all the difference. The right tool is a JIS screwdriver, which just fits better in a JIS screwhead and is designed to let you apply more torque than a Phillips driver.

"The Phillips system was invented for use in assembling aluminum aircraft, with the object of preventing assemblers from tightening screws so tightly that the aluminum threads strip.

The driver will “cam out” before that happens. The Phillips driver has four simple slots cut out of it, each slot is the result of two machining processes at right angles.

The result of this process is that the arms of the cross are tapered and has slightly rounded corners in the tool recess.

Phillips is designed so that when excess torque is applied it will cam out rather than ream the recess and destroy the bit.

Japanese Industry Standard: Often improperly referred to as Japanese Phillips. Commonly found in Japanese equipment, JIS looks much like a Phillips screw, but is designed not to cam out and will, therefore, be damaged by a Phillips screwdriver if it is too tight. Heads are usually identifiable by a single raised dot to one side of the cross slot.

Most people and companies outside of Japan have absolutely no idea what they are. With the similarity in appearance to the Phillips the screws are often damaged in removing and installing with the wrong tools.

JIS tends not to cam out like Phillips. The JIS driver can be used on Phillips quite easily but not reciprically (sic). Drivers are easily available in North America, try Amazon and/or eBay.

JIS-spec cross-head screws are generally marked with a single raised dot or an “X”. JIS always fit Phillip fasteners, but because of slight design differences, Phillips drivers may not fit JIS fasteners. (unless the tip is ground down a bit)."

Easily available via Amazon or eBay

This Vessel Megadora 980 Impacta P2x100 #2 Cross Point Impact JIS Screwdriver, which combines an impact driver with a screwdriver, will save you untold grief . An internal cam mechanism turns the tip 12 degrees per hammer blow

Non-impacted JIS screwdrivers

Last edited: