Nice work. Mine are currently off the bike as part of my LED end/grip relocation... knowing I'm likely to replace the stocks in the future all this makes me wish I sprung for those already.

I am way behind my personal schedule of a few days to get all the handlebar stuff done and then proceed with suspension mods, but that's OK because it's Winter and that's pretty much the only perk of an off season. No pressure to get back on and ride because you're missing good weather. So I have another month+ to be sure I don't just bully through it, and take my time to get it all done right.

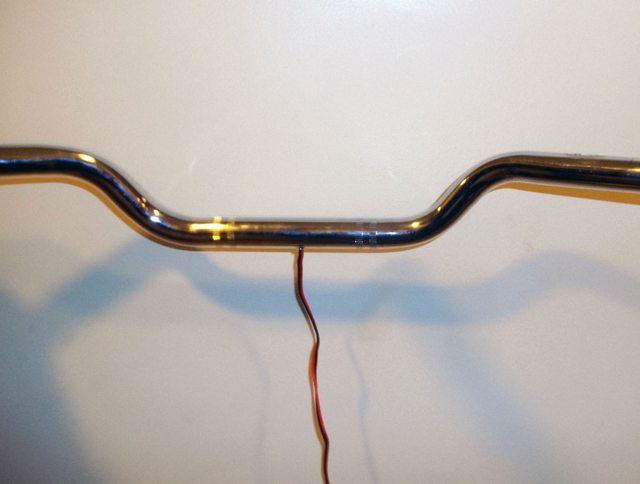

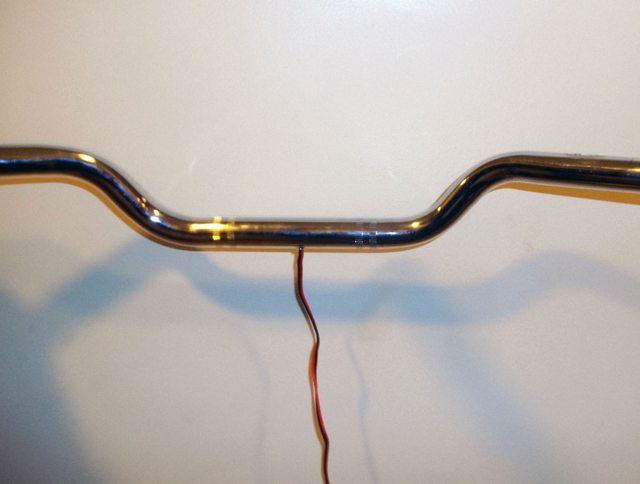

Here's where I lest left you guys I think:

That spacer looks a little rough yet, but what the hell I'll toss it in there until I can come up with a new one. Found a metric bolt that will work to replace the rusty crap this shipped with. The rest of the bolts can be re-used from what's on the bike already.

By the time I got done derusting that little spacer it was so dull it didn't matter what else I did to it... it wasn't coming back to shiny metal, and so I swung by an Ace Hardware and found a perfect matching new chrome spacer to replace it. Upon assembly I noticed that not only was the correct inner diameter and length necessary, but also the correct outer diameter as it needs to fit into a little recess created by the sub-frame bolt.

Not wanting to bother running back and finding some spacer that was not only the correct ID but also the correct OD... I settled for a different way to make it shiny.

Paint. It's scuffed as hell so it shouldn't have a problem taking it, and I had to paint the 2nd piece in that photo from it's former white PVC self anyway. More on what that's for in a minute.

This weekend I helped a friend setup his new drill press, and we proceeded to take it on it's maiden voyage of drilling a 1/4" hole in my handlebars for those new LED ends. The hole cut beautifully, and naturally has very sharp edges. Plan A on being able to fish the cables through without cutting them to bits when pulled against that sharp cut was a small rubber grommet. Unfortunately I came up shy in my hardware store search of one that had the correct diameter and didn't compress too much to make pulling cables too difficult. So I went with plan B which was cutting the narrow end off a plastic weatherproofing wire insulator, and sliding it into the hole just as soon as the fished cable came through. That allowed me to finish pulling the cable through without having it get cut up by the steel hole.

Result (of just the clutch side)

A very intact cable run through some handlebars.

That + a rubber washer being compressed has the new LED end completely snug on it's own - without having to rest inside the edges of the grip at all as originally (and poorly) planned.

So the clutch side install is done as far as the bar end being on, the grip being on, and the cable being run through a newly drilled hole without being cut to shreds. Since these bar ends are intended to just butt right up against the end of the handlebar I have to leave a space for the throttle side so it's not rubbing on the throttle grip and screwing with the return. Except I really don't want to leave a space at the end of the hollow handlebars where all kinds of moisture can collect and immediately go to work on rusting up the handlebars.

So I got a PVC coupler, and cut it in half. Then spent a bit of time with the Dremel slightly expanding it's inner-diameter to fit the LED end's stem, and shaving down the outer diameter to just greater than the precise diameter of the handlebars. Then painting it. This sort of work is not at all in my manly man nature which is to just pound **** until it half ass fits. So I've spent about 10-20 minutes a day over the last week worrying about fractions of millimeters being shaved while keeping a level edge for the bar end to rest on.

It's freezing outside so I'm giving 48 hours indoors at 62-68 degrees for the coats of paint to dry. Then I'll go ahead and wrap this up with some heatshrink over the cables coming out the bottom of the handlebars to look as professional as possible. I've also got some clear caulk to seal that, and seal the throttle side spacer inside the bar. Shouldn't really be any way for excessive moisture to get in, and caulk is easy enough to remove should I ever need a new pair of bars or new ends. I plan to leave a couple inches of cable slack inside the bars though, so I can have enough slack for grip changes and put some splices on the ends if just the signals ever need to get changed. So I am considering the hole in the bar and all that to be as good as permanent, because balls to doing all this twice.

Very minor, but very time-consuming and detailed work. Extremely glad for an off-season right now or all would more than likely be on the bike and completely half assed.

![Bovemanx Motorcycle Phone Mount Holder, [150mph Wind Anti-Shake][7.2inch Big Phone Friendly] Bike Phone Holder, Motorcycle Handlebar Cell Phone Clamp, Compatible with iPhone 16 Pro Max Smartphones](https://m.media-amazon.com/images/I/51F+1sontPL._SL500_.jpg)

![Aomiker Motorcycle Phone Holder Mount - [Metal Extension Arm] [Dual Vibration Dampener] Motorcycle Cell Phone Mount, Bike Phone Handlebar Clamp for iPhone 16 15 14 13 Pro Max Plus, 4.7-6.7" Smartphone](https://m.media-amazon.com/images/I/51gU2g5VxgL._SL500_.jpg)

![JOYROOM Motorcycle Phone Mount, [1s Auto Lock][100mph Military Anti-Shake] Bike Phone Holder for Bicycle, [10s Quick Install] Handlebar Phone Mount, Compatible with iPhone, Samsung, All Cell Phone](https://m.media-amazon.com/images/I/5113ZNM8R8L._SL500_.jpg)

![Lamicall Motorcycle Phone Mount Holder - [Dual Vibration Dampener] [720° Adjustment Arm] Motorcycle Cell Phone Holder, Bike Handlebar Phone Mount, for iPhone 16/15/ 14/13 Pro Max, 4.7-6.7" Phones](https://m.media-amazon.com/images/I/41g9IDInCIL._SL500_.jpg)