Doesn't that swap put the chain on the outside of the frame?

http://www.vmaxforum.net/attachment.php?attachmentid=8351&d=1242268386

To answer the Triumph Weight question, I would have to search thru all the old posts on XS11.Com.....I do recall dropping 1/2 the weight as the stock rear swingarm and wheel/shaft combo.

The other thing you will have to get use to when you go from shaft to chain is the loss of the Frame-flex that comes with these bikes....I also copied the Vmax's soilid mounts in billet and modified them for the 11. I have the Drawings also...I,m sure they are somewhere here on the site.....

Also I looked at a few different SSSA's....VFR800, RAM, and Ducati...... The Duc and Triumphs win hands down.....They are molded stronger than the others. And most importantly can be had for a song on The Bay all day.

SEAN previously wrote....

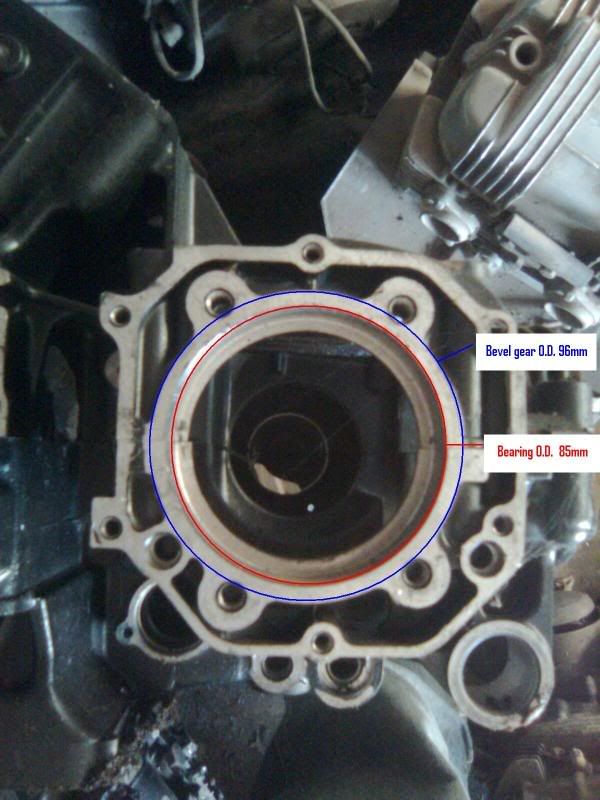

"Now, there is nothing saying you can't come up with a way to remove that outer nut and fab a sprocket carrier that attaches to it. Pull the rear half of the gear out and put a block plate in. Just leave the old work gear in place and not worry about it.

That may be the direction you should look at."

I also was looking at that possibility yesterday, although I hadn't removed that large pinion preload nut to see what the threads looked like and how many there were. I'm not sure I would trust a simple screw on sprocket carrier adapter.....

![Bovemanx Motorcycle Phone Mount Holder, [150mph Wind Anti-Shake][7.2inch Big Phone Friendly] Bike Phone Holder, Motorcycle Handlebar Cell Phone Clamp, Compatible with iPhone 16 Pro Max Smartphones](https://m.media-amazon.com/images/I/51F+1sontPL._SL500_.jpg)

![JOYROOM Motorcycle Phone Mount, [1s Auto Lock][100mph Military Anti-Shake] Bike Phone Holder for Bicycle, [10s Quick Install] Handlebar Phone Mount, Compatible with iPhone, Samsung, All Cell Phone](https://m.media-amazon.com/images/I/5113ZNM8R8L._SL500_.jpg)