Hey Guys some really really good news!!! :eusa_dance::eusa_dance::eusa_dance:

If you remember in the beginning I had to shorten the sender to prevent it from hitting the back of the tank.

Also because the tank is sloped up to I had to use some extra cork to keep it level which puts some stress on the bolts and the blind rivet nuts because they are not at the same angle.

Well I called the people that make the sender, CentroidProducts, and they have a solution.

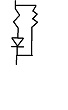

They make a 1/4" tubing sender that is bendable.

When you do your install you can put a small bend in the tube to angle the tube towards the front of the tank and clear the back part.

They are also making it with a dampening feature which along with the already built in dampening due to the design it will really prevent the slosh effect from our tanks.

Alos if you plan to do this and use a regular 90*, short sweep, gauge then you will need the dampening feature. Most of the short sweep gauges out there bounce a lot.

If you do use a full sweep gauge, there is only one out there that works with the sender

Marshall Instruments. (google them)

If you get this gauge u have to have your sender programmed with a LINEAR curve.

This is the setup I am going with

Marshall Gauge; Centroid 11" 3 terminal sender with bendable tubing, linear curve and dampening feature.

This is what I have found to provide the

absolute best reading all the way down to 1/2" off the bottom.

This will allow your OEM light to come on as usual and then still have your gauge reading how much fuel you have left.

Also the Marshall Instrument gauges have an alarm feature that you can program yourself.

Lets say you set it to 1/8 of a tank, the amber back lighting will flash slowly 1/8 and lower. It will also light an external light if you want it to, you can put a light up by your speedo and it will alert you when you are at your predetermined setpoint.

I am excited about all this. :biglaugh::biglaugh::biglaugh::eusa_dance::eusa_dance::eusa_dance:

unk:

unk:

unk::clapping::clapping::clapping: