So here is my settings after playing, testing and trying to find advanced tips on many forums...

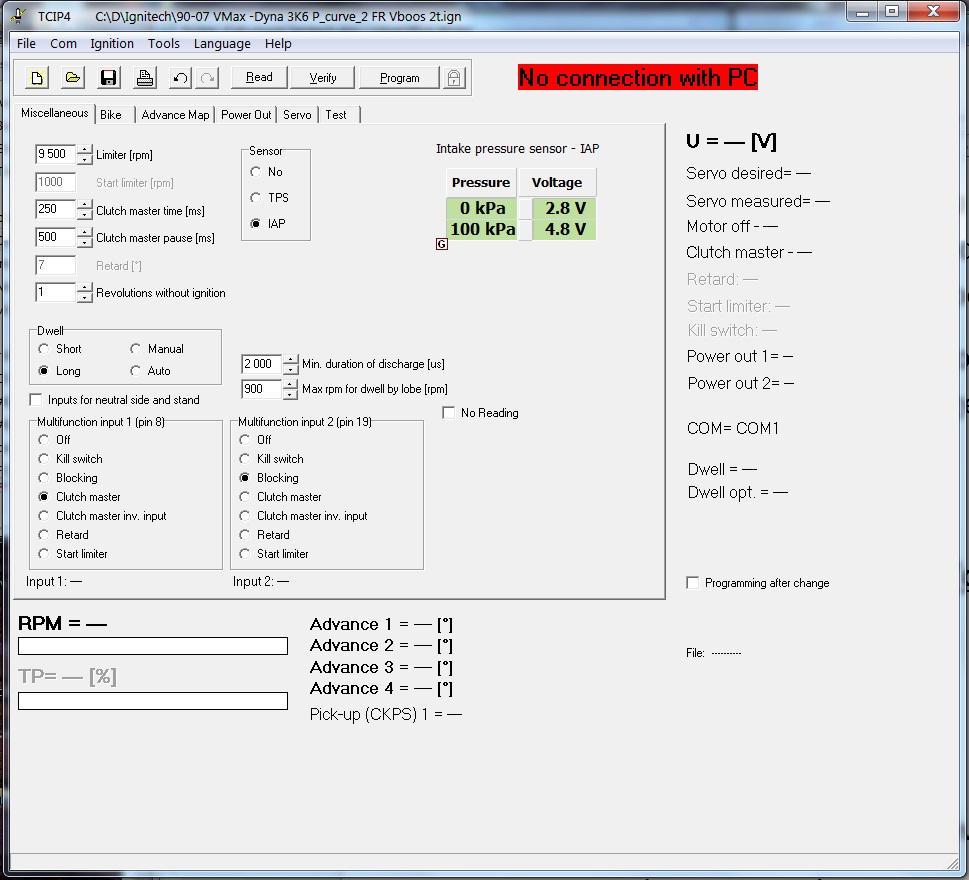

MISCELLANEOUS

250 ms for Clutch master time (shifting is easier)

500 ms Clutch master pause (enough between shifts)

1 rev without ignition, a little fuel before ignition backpressure (easier start, better for starter)

For sensor settings, i decided to go differently because i don't feel the throttle blipping good and accurate, so:

0 Kpa setting.

We don't need to find the max vacuum value voltage, we need the voltage value at max vacuum advance, in the EUR manual, max vacuum advance is at 270mmHg (greater values than US for better part throttle grunt).

So i connected the Carbtune to the carb 2 vacuum port and set the idle (idle scew) till it reach 270mmHg, i note 2.8V on the Laptop.

So 2.8V is my 0Kpa value and it will be my Max vacuum advance setting in the map

100Kpa, At WOT, there is no vacuum so i took the Voltage value shown with engine not running : 4.8V

4.8 is my 100 Kpa value and will be my mechanic advance setting in the map.

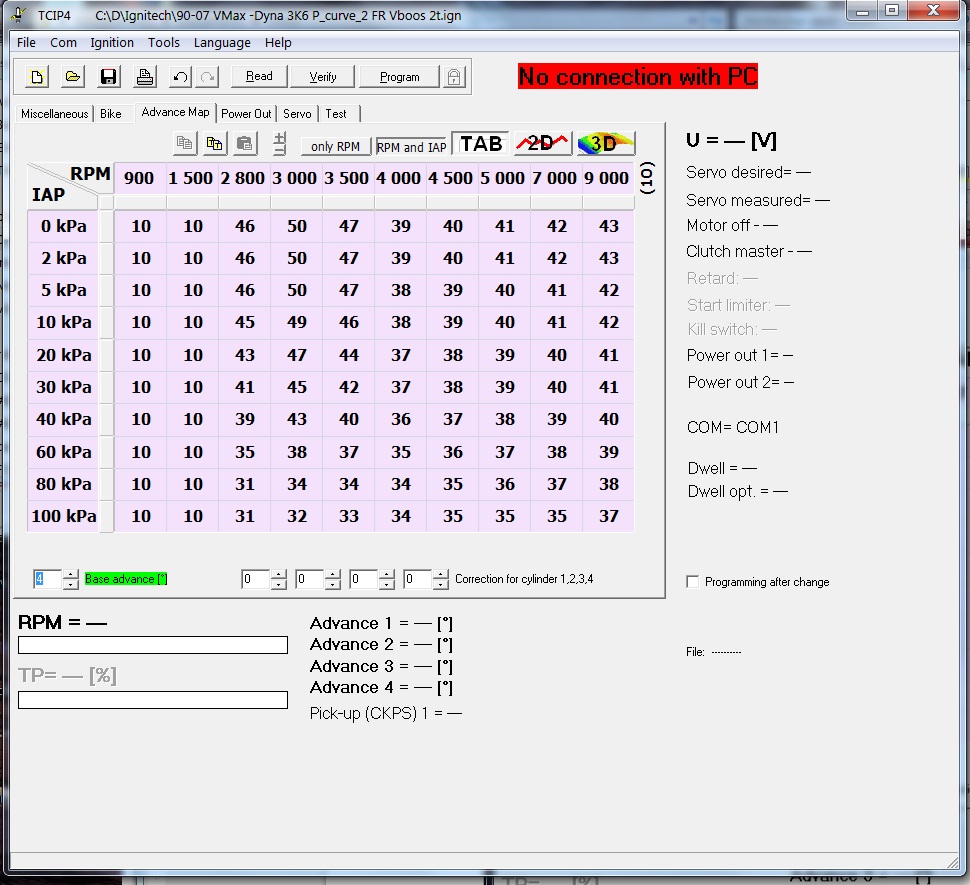

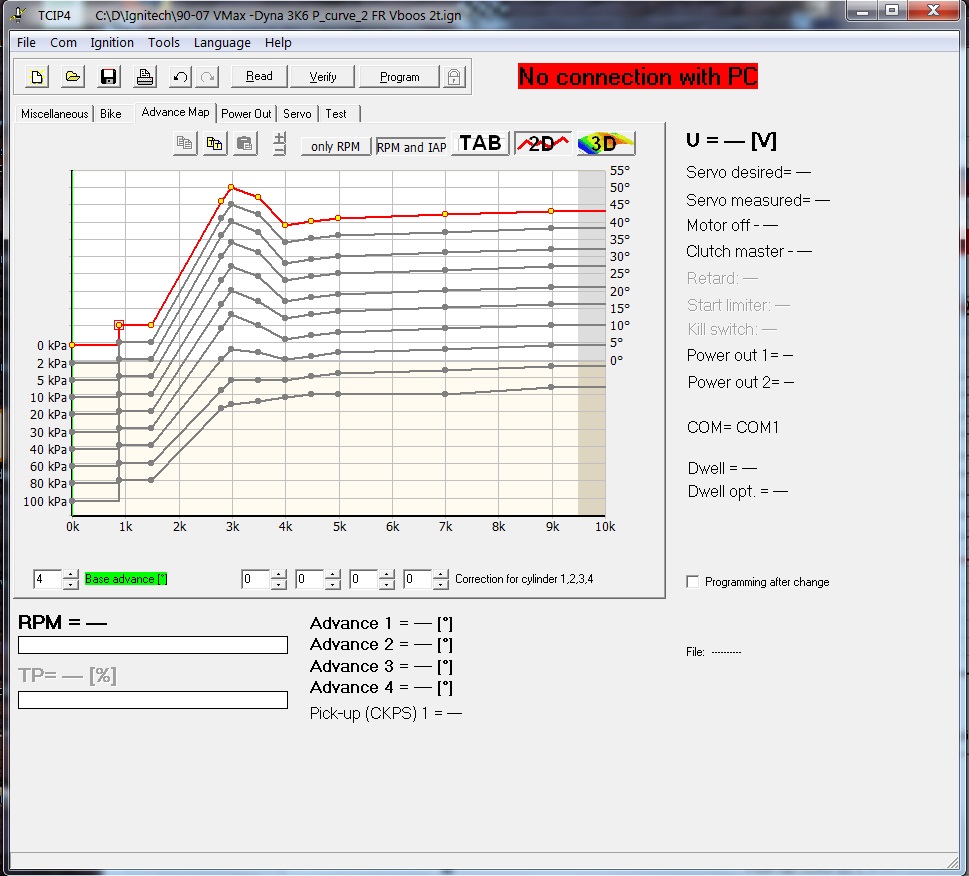

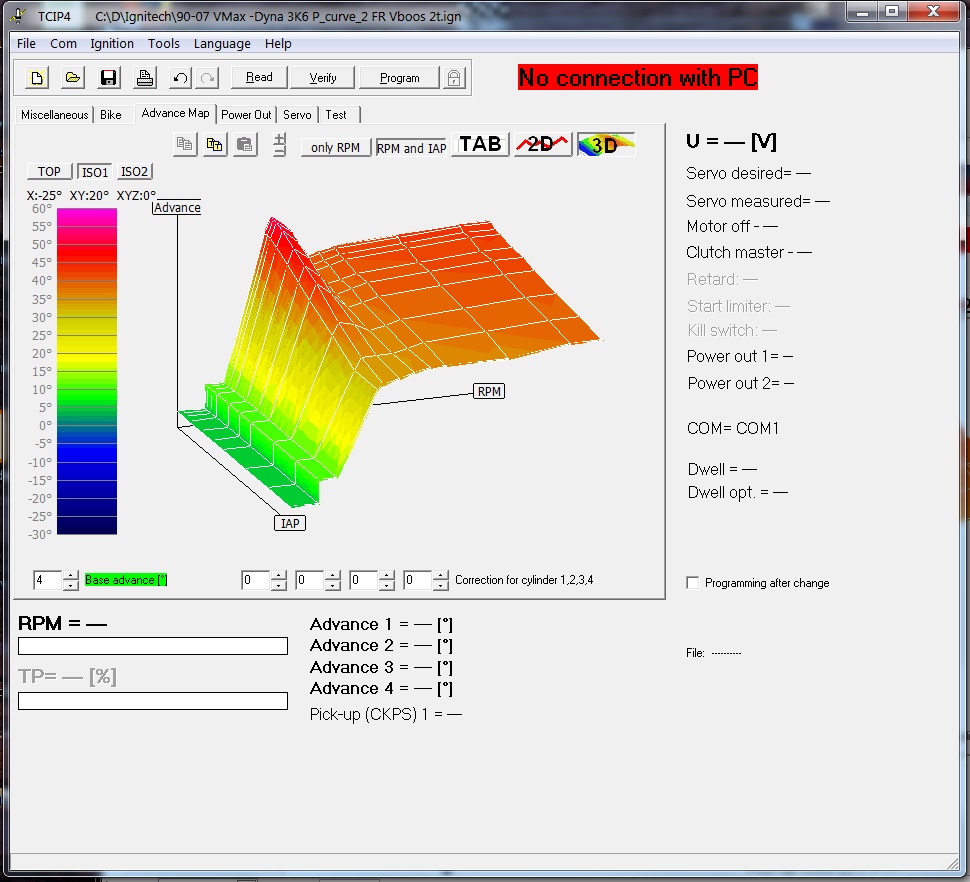

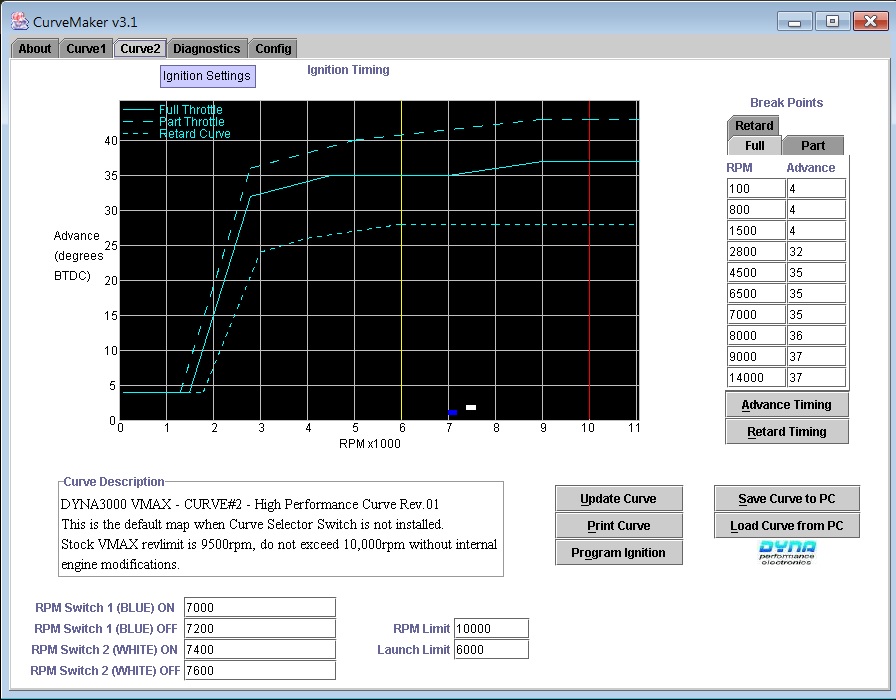

ADVANCE MAP

This is the WOT advande curve of the Dyna3K programmable ver.

I breeded it with the higher vacuum values of the stock EUR TCI (way better for part throttle and cruising around 3000 RPM.)

I set the base advance at 4°till 900 RPM (where dwell by lobe stops) to make life easier for the starter.

So at 1100 RPM, the initial advance is 10°, way better than stock 4°, engine is running better at cold without choke!

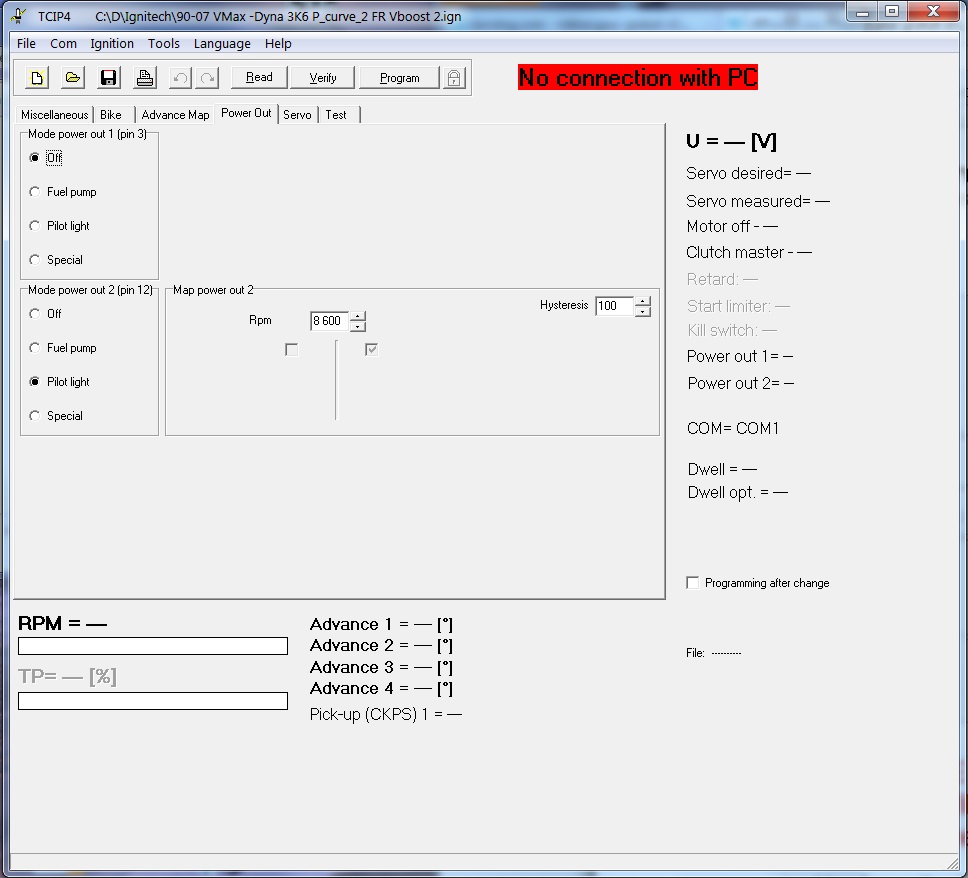

POWER OUT

Shift Light activated, setting is 8600 for now, probably need more fine tuning.

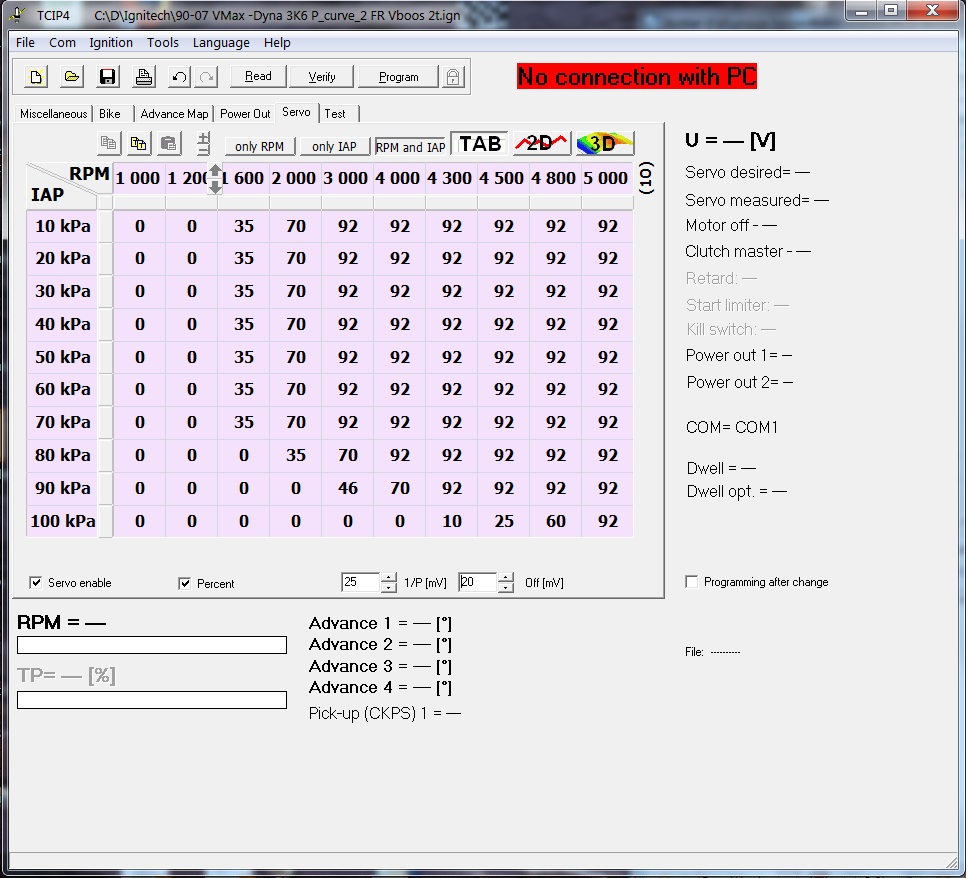

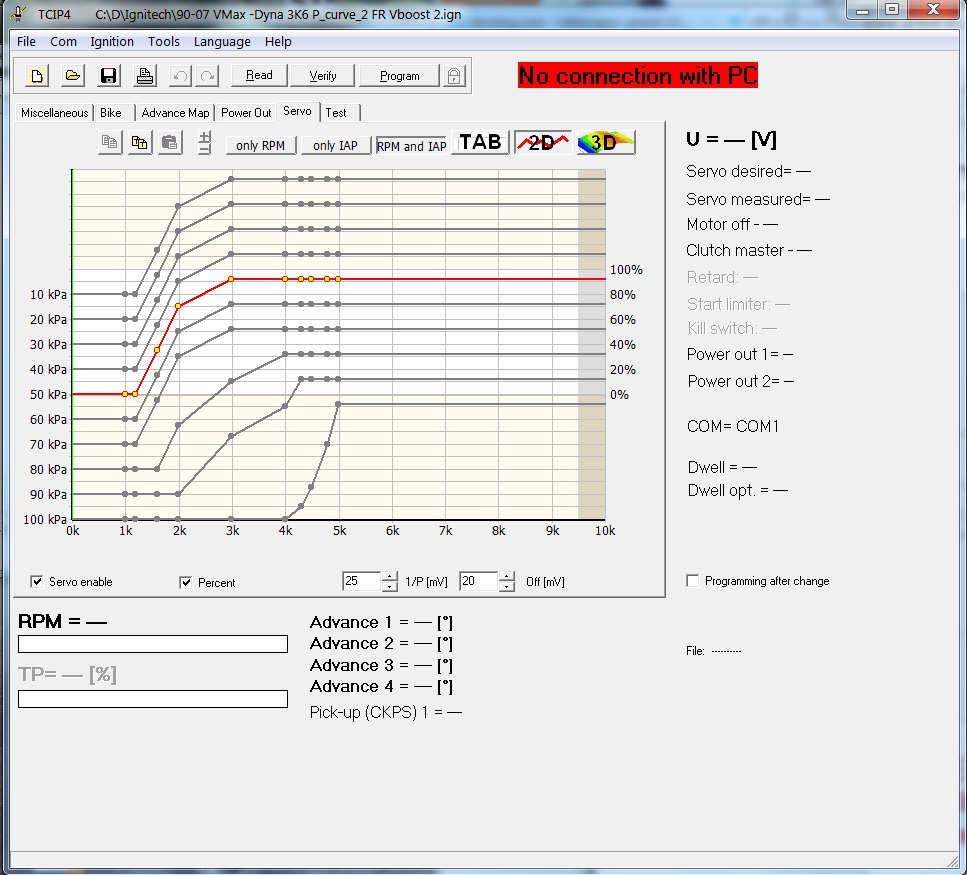

SERVO

I made a mix between stage7 and stock Vboost.

With Stage 7 at low rev, we have grunt on part throttle, but the more you open the throttle, the lower the grunt is (intake air speed drop too low) so.

I set it to be almost always open on part throttles openings and to be shutted under about 5000 RPM at WOT (why not 6000, because some ET tests seems to give better results with opening at 5000 instead of 6000 or 3000)

Closed at idle for clean idle...

25 1/P [mV] because under i hear the servomotor moving when engine stopped, if i put my finger on the pulley i can feel micromoves, no more engine noise (but something else) and move at 25

20 Off [mV] because under (when 25 1/P set) i ear some "digital" noise (like CD readers when seeking), no more noise at 20.

This way i know that the servo moto is really steady.

![Bovemanx Motorcycle Phone Mount Holder, [150mph Wind Anti-Shake][7.2inch Big Phone Friendly] Bike Phone Holder, Motorcycle Handlebar Cell Phone Clamp, Compatible with iPhone 16 Pro Max Smartphones](https://m.media-amazon.com/images/I/51F+1sontPL._SL500_.jpg)