I have a question about the clutch master time setting. I will use Thor's current setting as an example. In his case, the ignition will be interrupted for 250ms. And the interrupt can be performed every 500ms. Let's say that I am staging for a run down the strip. I have the clutch pulled in, RPM at 5000, and waiting for the green light. Will the ignition be interrupted for 250ms every 500ms continuously as long as the clutch lever is pulled in? Or, does the clutch have to be released to "reset" The timer?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The IGNITECH TCI thread

- Thread starter wildweasel_pt

- Start date

Help Support VMAX Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

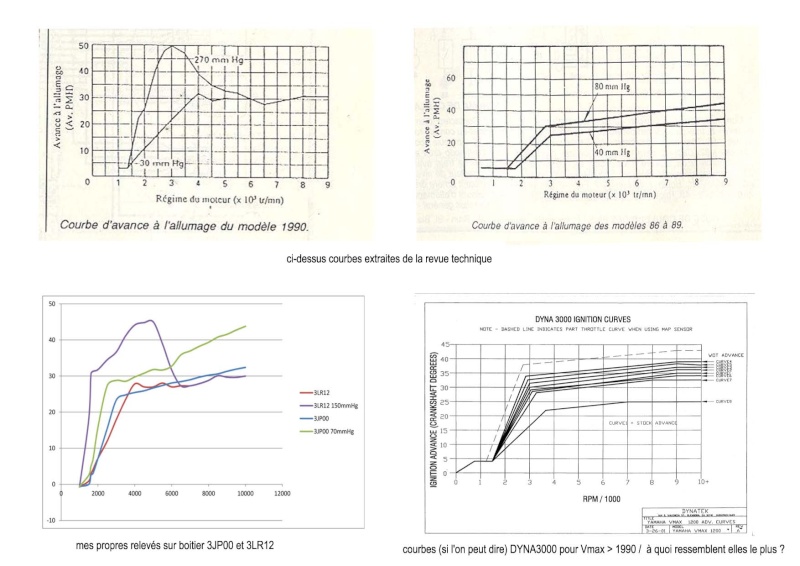

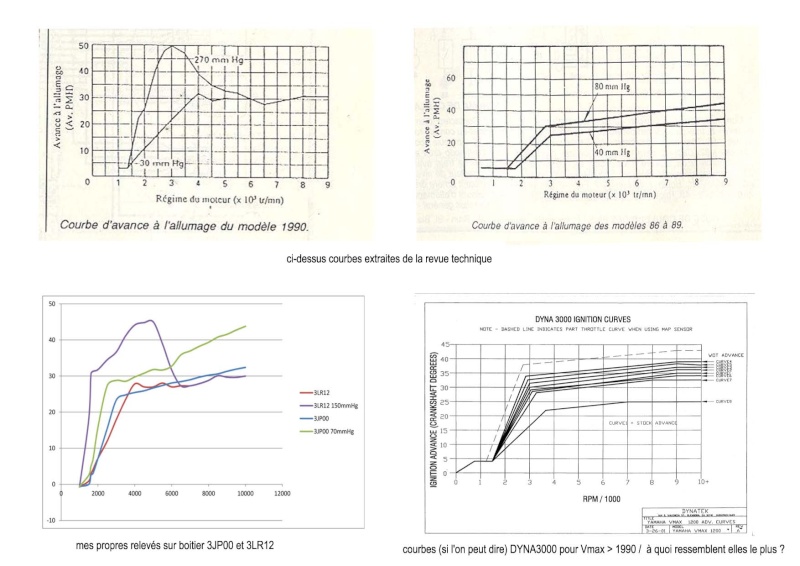

The part thottle advance max values i set: 50° at 3000 RPm (270 mm HG) and curve shape to 4000PM are the Yamaha stock ones for 90=>EUR (with same camshaft as US) so no worries about detonations. those values are safe

From 4000 to 9500 this is the part throttle advance max curve of the new Dyna3K, may be too high, may be not.. At partial load it shouldn't create detonations.

I think this is better to set the max part throttle advance at 270mmhg than 80 or 40. The gap is wide and safer between 270 and 0 than 40 and 0

For detonation camshaft curve does play some role....but octane of the gas plays a higher role? What octane do you run over there.....and is it RON or MON? Here it is an average of the 2.

In the 2nd link the poster had talked about not being able to hear the detonation because the Vmax is a noisy engine.

Can you send me as a PDF...etc a copy of the 90 and up ignition curve....and is that with....or without V-boost? V-boost being open tends to lean out the A/F ratio. Yes your getting extra fuel.....but your also getting twice the amount of air.

thor_eyerdhal

Well-Known Member

Here premium is 98 RON 88 MON => 93 average for you.

EUR curve is without Vboost of course...

The WOT EUR curve is more conservative than the US one, only 31°max (for power reduction too)

Up left picture :

Yes opening Vboost lean out the mixture, at any RPM (even if it smell worst) my Innovate showed me this fact constantly

EUR curve is without Vboost of course...

The WOT EUR curve is more conservative than the US one, only 31°max (for power reduction too)

Up left picture :

Yes opening Vboost lean out the mixture, at any RPM (even if it smell worst) my Innovate showed me this fact constantly

That makes sense. You could probably go to the equivalent of Dyna curve #3, for more HP. I loaded it.....but it didnt like the 87 octane fuel. During my next dyno run, I plan on adding some octane boost.....or 91 fuel, and reloading it....and see what happens.

RempageR1

Well-Known Member

@thor_eyerdhal,

Thank you for sharing your map and theory behind it! I`m in the Netherlands and use eur95. I`m going to load it and let you know how it performs with this fuel... 17th or april I`m going to race my max @ Assen so that should be a good test .

.

Thank you for sharing your map and theory behind it! I`m in the Netherlands and use eur95. I`m going to load it and let you know how it performs with this fuel... 17th or april I`m going to race my max @ Assen so that should be a good test

thor_eyerdhal

Well-Known Member

@thor_eyerdhal,

Thank you for sharing your map and theory behind it! I`m in the Netherlands and use eur95. I`m going to load it and let you know how it performs with this fuel... 17th or april I`m going to race my max @ Assen so that should be a good test.

Do you have stock carbs or Stage7/Morley ?

If stock, it should work, i want to know...

If Stage7/Morley (like mine) it is very hard to avoid a very rich spot around 4000 when vboost is closed.

I have others maps (same advance curve) with others Vboost settings if you want

$16.19

$17.99

MELASA Fleece Lined Winter Cycling Beanie with Holes for Glasses - For Men, Women

HNXCHUANG

RempageR1

Well-Known Member

Do you have stock carbs or Stage7/Morley ?

If stock, it should work, i want to know...

If Stage7/Morley (like mine) it is very hard to avoid a very rich spot around 4000 when vboost is closed.

I have others maps (same advance curve) with others Vboost settings if you want

I`m running a stock `85 Canadian bike with a TPS sensor and factory needles. Since the vboost controller cannot handle short dwell time (needed with COP`s), the Ignitech is now also controlling the Vboost. I`ve been trying a 3d Vboost map but found no real benefit (not verified on Dyno). Now it`s back to 2d.

Your advance map is now uploaded to my Ignitech and it`s ready to be tested. It can however take some days before I have time to do so but will report back when I have!

thor_eyerdhal

Well-Known Member

This map works with IAP, don't use the TPS without some mods...

RempageR1

Well-Known Member

This map works with IAP, don't use the TPS without some mods...

Hi,

Could you please elaborate on that? The TPS should pick up throttle position changes earlier than IAP would so I assumed it would be compatible.

Thank you!

thor_eyerdhal

Well-Known Member

i never tried TPS but using percent (easier withour knowing voltage values), for ignition timing as a starting base you should try my 100Kpa values with 100% TPS and my 0Kpa values with 0% TPS.

But a fixed throttle Position isn't a fixed vacuum value, so adjustments will be needed

For ignition i think IAP is better than TPS because it is what motor want, not TPS, and changes are very fast too...

For Vboost map i think TPS is better, so you could try the same map replacing Kpa with TPS percents...

But a fixed throttle Position isn't a fixed vacuum value, so adjustments will be needed

For ignition i think IAP is better than TPS because it is what motor want, not TPS, and changes are very fast too...

For Vboost map i think TPS is better, so you could try the same map replacing Kpa with TPS percents...

RempageR1

Well-Known Member

i never tried TPS but using percent (easier withour knowing voltage values), for ignition timing as a starting base you should try my 100Kpa values with 100% TPS and my 0Kpa values with 0% TPS.

But a fixed throttle Position isn't a fixed vacuum value, so adjustments will be needed

For ignition i think IAP is better than TPS because it is what motor want, not TPS, and changes are very fast too...

For Vboost map i think TPS is better, so you could try the same map replacing Kpa with TPS percents...

Hi,

I`m sorry for the confusion, I only copied the timing values from your screenshots and used it with my TPS settings. I understand that TPS is not the same as IAP but indeed used the TPS as it is easier to setup. Yesterday I tested your values and the bike seems to like it. No indication of detonation anywhere, no power gaps (that I could detect). I also made the Vboost kick in earlier and that also seemed to help. So lookin` good!

Thanks again.

thor_eyerdhal

Well-Known Member

if it works, great !

Yes i change vboost kikin too, with my Morley kit this is better with 3000 RPM full opening...

Yes i change vboost kikin too, with my Morley kit this is better with 3000 RPM full opening...

So, I was having a hot start issue for the past couple of weeks. I figured out the cause and figured I'd share it here. On the "miscellaneous" tab, there is a setting "revolutions without ignition" I changed that to 1. This allows the engine to spin one full revolution before there is any spark. That allows the starter to get up to full speed before the first spark. Makes for much easier starting cold or hot. This may have been discussed before, but I usually learn everything the hard way.

Here is the tune that I'm currently running. It is a little different interpretation of the Dyna curve #3 with Vboost open full time. The issue that I found with most tunes that smooth out the transition between WOT and part-throttle was that they made for really squishy, boring throttle response with the vboost open full time.

If you take a look at the IAP/TPS section, I am running IAP. I have the voltages set at 0V-5V. Here is where I need some help from somebody as I am not at home with a full shop of stuff to play with. Any Volunteers?

Here is the test I would like to be able to do, but can't:

1. Program your ignitech with the attached map and keep the computer plugged in

2. Disconnect the MAP sensor hose from cylinder #2 and put a cap over the nipple on the intake.

3. Connect a MightyVac or similar vacuum pump with a gauge to the MAP sensor hose.

4. Start the bike and record the IAP voltage with the bike running and no vacuum on the MAP Sensor.

5. With the bike still running, pull a 100kpa(14.5psi) vacuum on the MAP sensor and record the IAP Voltage.

If Someone could check that, it would be most helpful. As always, any constructive criticism is always appreciated

If you take a look at the IAP/TPS section, I am running IAP. I have the voltages set at 0V-5V. Here is where I need some help from somebody as I am not at home with a full shop of stuff to play with. Any Volunteers?

Here is the test I would like to be able to do, but can't:

1. Program your ignitech with the attached map and keep the computer plugged in

2. Disconnect the MAP sensor hose from cylinder #2 and put a cap over the nipple on the intake.

3. Connect a MightyVac or similar vacuum pump with a gauge to the MAP sensor hose.

4. Start the bike and record the IAP voltage with the bike running and no vacuum on the MAP Sensor.

5. With the bike still running, pull a 100kpa(14.5psi) vacuum on the MAP sensor and record the IAP Voltage.

If Someone could check that, it would be most helpful. As always, any constructive criticism is always appreciated

Attachments

thor_eyerdhal

Well-Known Member

Trying to match the KPA range is useless, you can define it as you want.

What you need :

-The WOT Voltage value, you can tell 100Kpa = WOT.

At WOT vacuum should be 0 so you've got the 100Kpa Voltage with Map sensor not plugged or engine stopped.

-The 40 or 80 inhg voltage value or 270inHg on EU Models (better choose this one)

Put a vacuum gauge on the vacuum line, set your idle to reach 40-40 or 270. Remove the gauge and plug the map sensor then read the voltage of the map sensor.

It will be you Max vacuum advance voltage.

You can set it at the 0Kpa line or whatever is your first line in the board

What you need :

-The WOT Voltage value, you can tell 100Kpa = WOT.

At WOT vacuum should be 0 so you've got the 100Kpa Voltage with Map sensor not plugged or engine stopped.

-The 40 or 80 inhg voltage value or 270inHg on EU Models (better choose this one)

Put a vacuum gauge on the vacuum line, set your idle to reach 40-40 or 270. Remove the gauge and plug the map sensor then read the voltage of the map sensor.

It will be you Max vacuum advance voltage.

You can set it at the 0Kpa line or whatever is your first line in the board

Hello

I hope it is ok to join this thread. I live in Norway and have an european V-Max. Recently I installed this Ignitech unit. The bike runs well with the default IGN file, but I am having problem on setting the voltage levels. When the engine is idling at 1000 rpm, the voltage level fluctuate quite significantly.

Helge

I hope it is ok to join this thread. I live in Norway and have an european V-Max. Recently I installed this Ignitech unit. The bike runs well with the default IGN file, but I am having problem on setting the voltage levels. When the engine is idling at 1000 rpm, the voltage level fluctuate quite significantly.

Helge

Mine does the same. It also shows a really low voltage like 11.5V. I'm thinking that I may need to go through the harness and clean or eliminate some connectors.

RempageR1

Well-Known Member

Connectors might help but i would go for a MOSFET rectifier. Those units give way more power at idle. If you search this forum you`ll find a lot of options.

I did it like this:

http://vmaxforum.net/showthread.php?t=19548

I did it like this:

http://vmaxforum.net/showthread.php?t=19548

I already have a mosfet unit and voltage is steady when reading across the battery. The readout on the pc screen from the ignitech is still reading low and bounces around quite a bit. Already addressed all of the usual charging issues and fixed them. I'm thinking that there is a weak connection somewhere in the harness or fuse block. Haven't had time to tear into it yet. When I do get to it, I'll post up a new thread.

RempageR1

Well-Known Member

Allright then a lot is already done. First check the voltage across the battery so you know if it`s a alternator issue or it it`s beyond the battery.

Similar threads

- Replies

- 5

- Views

- 395

![Bovemanx Motorcycle Phone Mount Holder, [150mph Wind Anti-Shake][7.2inch Big Phone Friendly] Bike Phone Holder, Motorcycle Handlebar Cell Phone Clamp, Compatible with iPhone 16 Pro Max Smartphones](https://m.media-amazon.com/images/I/51F+1sontPL._SL500_.jpg)