satariel666

Well-Known Member

Cool. Thank You for the mesurments. It will save me a lot of time.I have such dimensions turned out. in mm

Now I can tell that flywheels were slightly diffrent beteween old and new type.

My mesurments from pre 90 flywheel are slightly diffren.

I will set those mesurments!

We just need to specify the tooth shape.

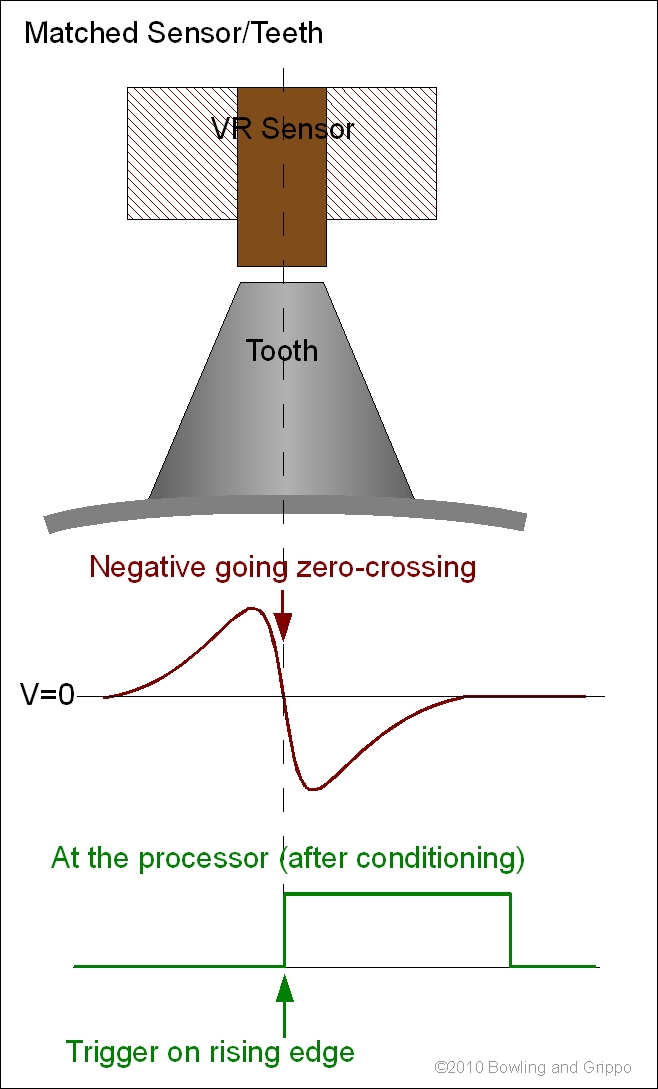

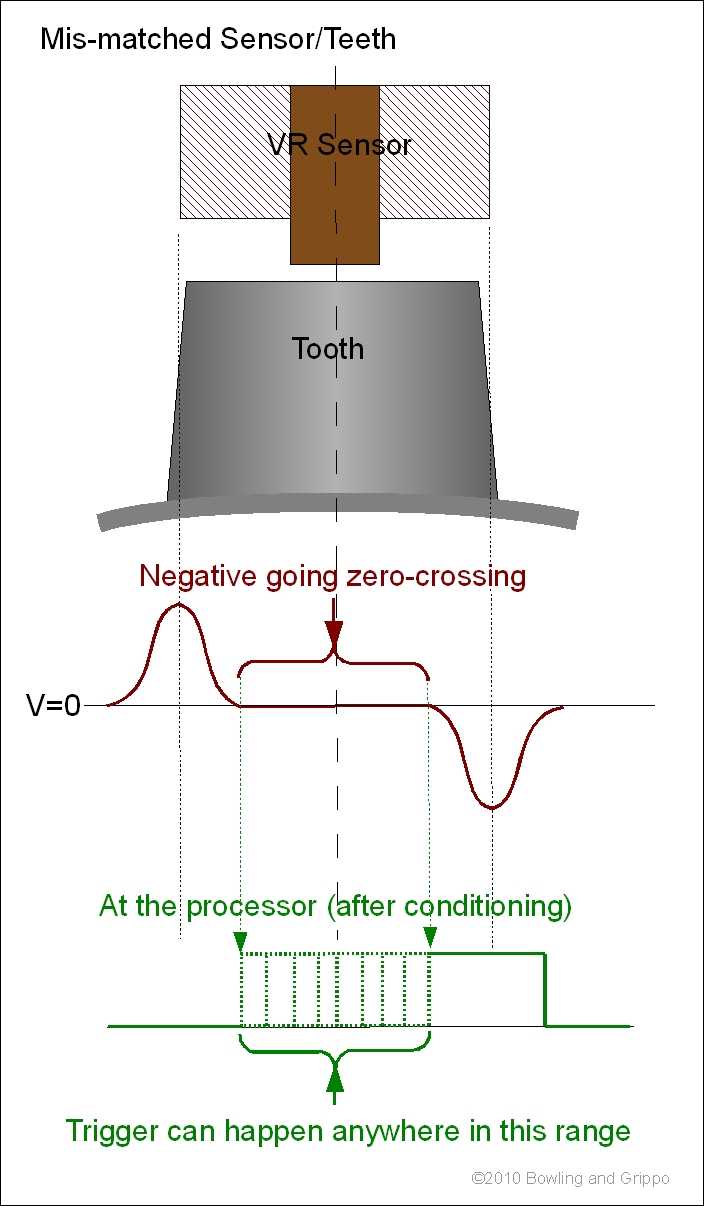

Question: what tooth shape will be the best ?

-round, just like in the drawning above

-symmetrical triangle

-non symmetrical triangle

Just like here, in those pics.

Look at the BEST TOOTH SHAPE.